150 years ago, a large amount of dissolved lithium was discovered in Cornwall, UK, in a hot spring some 450 metres underground. However, in the 19th century world there was no need for this mineral, so it was not taken into account. Until now (and it’s more valuable than petrol).

A 150-year-old underground discovery resurfaces: now what is it for?

This geothermal lithium deposit is one of the largest in the world. The hot springs found underground contain an incredible amount of the mineral in liquid form: 8 to 10 times the concentration found in hot springs that have been explored and are now being exploited.

What is it used for? It has become a key element in the energy transition as it is used in the manufacture of batteries to store energy in electric cars, mobile phones and computers. That is why in autumn 2020, interest in this geothermal lithium mineral seam reappeared.

What is geothermal lithium and why is it better than conventional lithium?

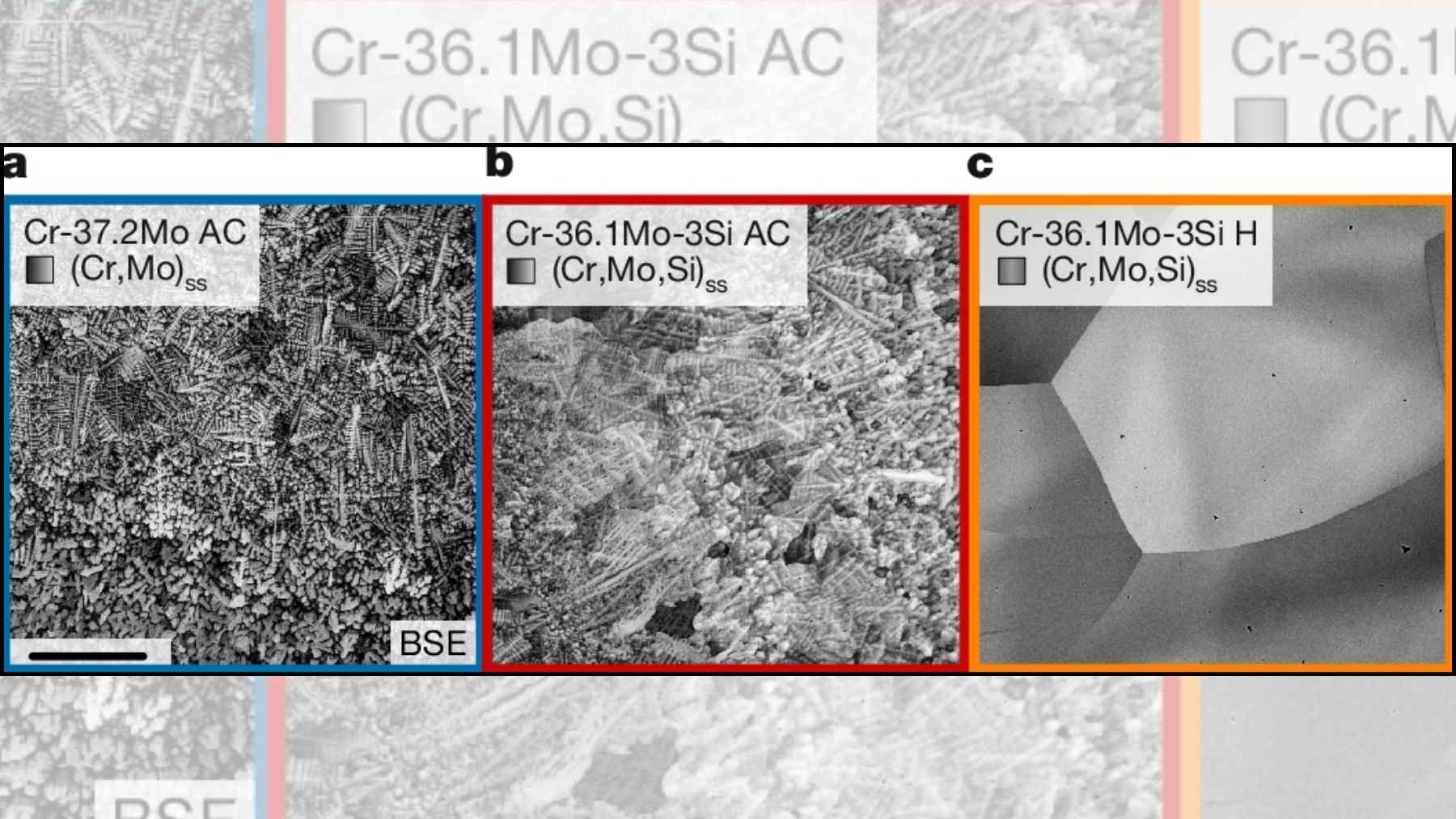

Geothermal lithium, which is found in water underground, has a staggering concentration of 260 milligrams per litre. It is found in a hot, saline brine that has passed through rocks that are very hot, absorbing elements such as potassium, boron and, of course, lithium.

Mining companies Cornish Lithium and Geothermal Engineering, which are involved in the exploration and exploitation of this mineral, plan to use state-of-the-art advances to obtain lithium from the brine. They will use a method called direct lithium extraction, or LED.

It has been developed by companies based in Germany, the United States and New Zealand. It is used in mineralised water underground. Basically, it involves the use of ion exchange resin or nanofiltration techniques, which operate as a kind of chemical sieve.

So lithium is obtained selectively in the form of chloride and separated from other salts and minerals contained in the water. The compound is then recovered from the sieve by washing the resin beads. Water is then injected into the soil using wells for this purpose.

Finally, the lithium chloride is treated to remove the remaining contaminating salts and concentrated to create lithium hydroxide, which is the material from which the batteries are made. This method is sustainable, environmentally friendly and has a very small carbon footprint.

But it is cheaper than the conventional method of lithium extraction.

Lithium, obtained by traditional methods, comes mainly from brine deposits underground in dry lake beds, the largest reserves of which are in Argentina and Chile. They are also found in Australia, specifically in hard rock mines.

However, although these methodologies are much cheaper than LED, they involve three environmental costs: more than 15 tonnes of greenhouse gases are emitted for every tonne of lithium processed and ready for use.

In addition, large quantities of water are used, which at the end of the process is polluted forever. Finally, there is the use of land, especially in hard rock mines, where it is mined in the open pit and then ‘roasted’ after it is brought to the surface.

In conclusion, the myth that it was underground results in a mineral that was discovered 150 years ago which, because of its use in the energy transition, is far more valuable than oil. Moreover, it represents a large reserve that can be extracted using sustainable methods.