German researchers at the Fraunhofer Institute have created revolutionary foam ceramics that have a multifunctional coating, using photovoltaic oxidation to decompose persistent water pollutants. The systems, which are designed to be small-scale, energy-efficient, and environmentally friendly, expose functionalized surfaces to light to UV rays to make the surface produce highly reactive radicals that break down organic impurities that are typically found on the surface, without harmful by-products or need for extra oxidizing agents.

Revolutionary foam ceramics transform water purification technology

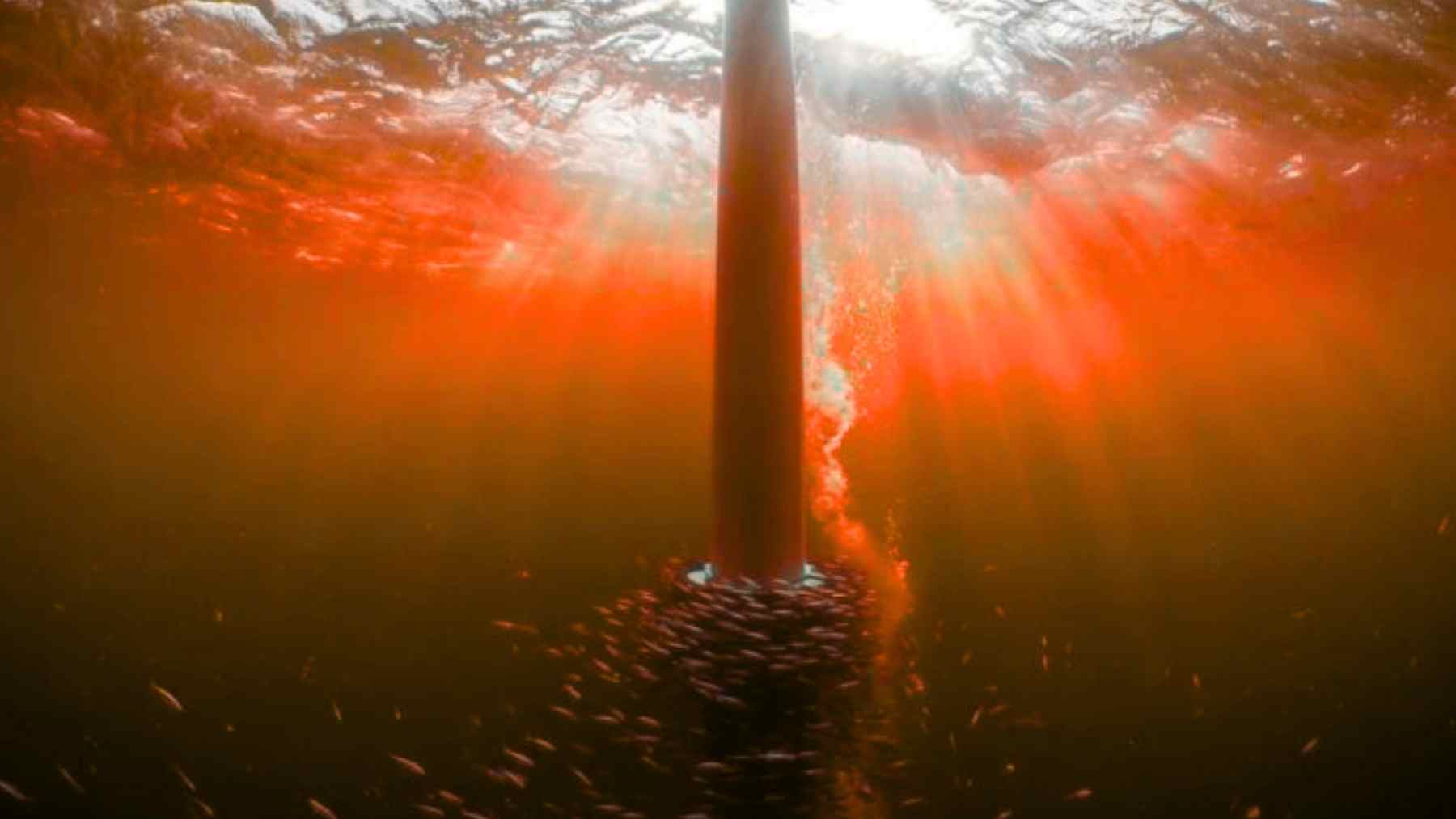

The Fraunhofer Institute for Ceramic Technologies and Systems, IKTS, is discovering new horizons. Innovative catalytic foams, whose functions are due to coatings on compact foam ceramics that break down even recalcitrant pollutants via photocatalytic oxidation, are being produced.

“When the functionalized surfaces are exposed to UV light, strongly aggressive radicals are generated in the treated water, which break down the organic impurities.” “This process does not generate any undesirable by-products and, on the contrary, does not need any further oxidizing agents such as ozone,” says Franziska Saft, a research scientist at Fraunhofer IKTS in Dresden.

This process relies strongly on the interaction between pollutant, catalyst, and light. The foam ceramics, due to their highly porous and network-like structure, offer spacious surfaces, which are suitable as carriers for various catalysts and adsorbents. In addition, due to the high open porosity of up to 90 percent, this allows for good transmission of light, with the best possible outcome for the photocatalytic process.

Multifunctional catalysts allow for unprecedented surface reactivity

“Extensive space for integration of multiple catalysts is offered in the form of our foam ceramics. This makes it possible to produce a very reactive surface area so that even in thin layers on the foam ceramide, we can carry out high catalytic conversions. The catalysts must be “stabilised on the foam such that they are not rinsed out with the wastewater flow,” adds Daniela Haase, who is also working on the project.

There are proven results in the real world for industrial applications

The scientists who conduct the research on the construction of the wastewater plants form cross-disciplinary groups. This involves the entire procedure from the selection and design of the multifunctional foam ceramics with an optimized geometry and catalyst coating and to adequate light sources, such as energy-efficient UV LEDs. The developed reactor design also specifically corresponds to the required features.

Customers include firms from the pharmaceutical, semiconductor, paper, dairy, and textile industries who require the pollutants to be broken down directly on site before they are released to wastewater treatment plants. This will not even allow them an entry into the aquatic environment. The current results between initially the present ceramic foam systems have been promising, with the initial pilot applications indicating that the present photocatalytic ceramic foam systems have been capable of breaking down pollutants in otherwise different industrial sectors.

On-site piloting always makes for customised treatment solutions

The concept allows for implementation into the existing systems and application-specific scaling and pilot implementation at the premises of the customer. This holistic approach ensures that all systems are tailored to suit the industrial application to which they are being deployed while delivering optimal performance at the highest engineering efficiencies for all levels of contamination and applications.

The German innovation in photocatalytic water treatment refers to a complete change of environmental protection technology, which can provide sustainable options to keep removing the persistent pollutant. This new technology puts Germany at the forefront of the water purification industry and sets the example of a technology that can be adopted on a larger scale to help us improve the terrible water pollution situation worldwide caused by industry and pharmaceuticals.