Sophia University in Tokyo, Japan is currently working on an ammonia-powered combustion engine. As a way to mitigate the planet’s carbon footprint and work towards global sustainability goals, carbon-free engines are one piece of technology which are receiving an uptake in attention across nations. The ammonia combustion engine is a joint research project by the university’s Faculty of Science and Technology’s Sophisticated Energy Research Center involving researchers in chemistry, materials science, and precision engineering.

Hydrogen may be the assumed obvious choice, but ammonia continues to surprise

Hydrogen technology has received significant traction across industry but specifically within the automobile world. This is because, unlike electrical vehicle technology, hydrogen supported engines can be made using existing combustion technology. Most significantly however, hydrogen does not release carbon dioxide in the combustion process and has a net emissions output of zero. The only byproduct is water.

However, Sophia University is taking a different route and is looking at the possibilities of using ammonia instead of hydrogen. Like hydrogen, ammonia also only produces a by product of water making it compatible with green energy goals. Professor Takashi Suzuki from the Faculty of Science and Technology describes how the interest by the university to turn their attention towards hydrogen was stemmed from Japan’s import constraints.

Japan’s import logistics make ammonia come out on top as the better contender

Japan is a small country which lacks natural resources. As such, for the country to develop clean energy solutions, the products need to be imported. If Japan wanted to shift their attention to hydrogen products, this would inevitably mean having to import hydrogen which has its own difficulties. Hydrogen can only be imported and transported in its liquid form after being cooled at -253 degrees Celsius.

Ammonia on the other hand, which would also have to be imported, is much easier to liquify. Further, it is already used in industry within Japan such as agriculture. As such, there is already infrastructure and safety processes in place for the importation of ammonia into Japan. If Japan wants to go green and produce alternative energy products, the process can be significantly eased if access to the resources is accessible.

Better logistics for Japan, but harder technological challenges at play

While importing ammonia is easier than hydrogen, the job gets significantly harder when having to use it with combustion engine technology. Ammonia is difficult to burn and for it to be effective, it usually is burned with petroleum gas, thus nulling the green energy approach. As such, researchers at Sophia University are experimenting with diesel technology and finding ways to reduce the amount of petroleum needed.

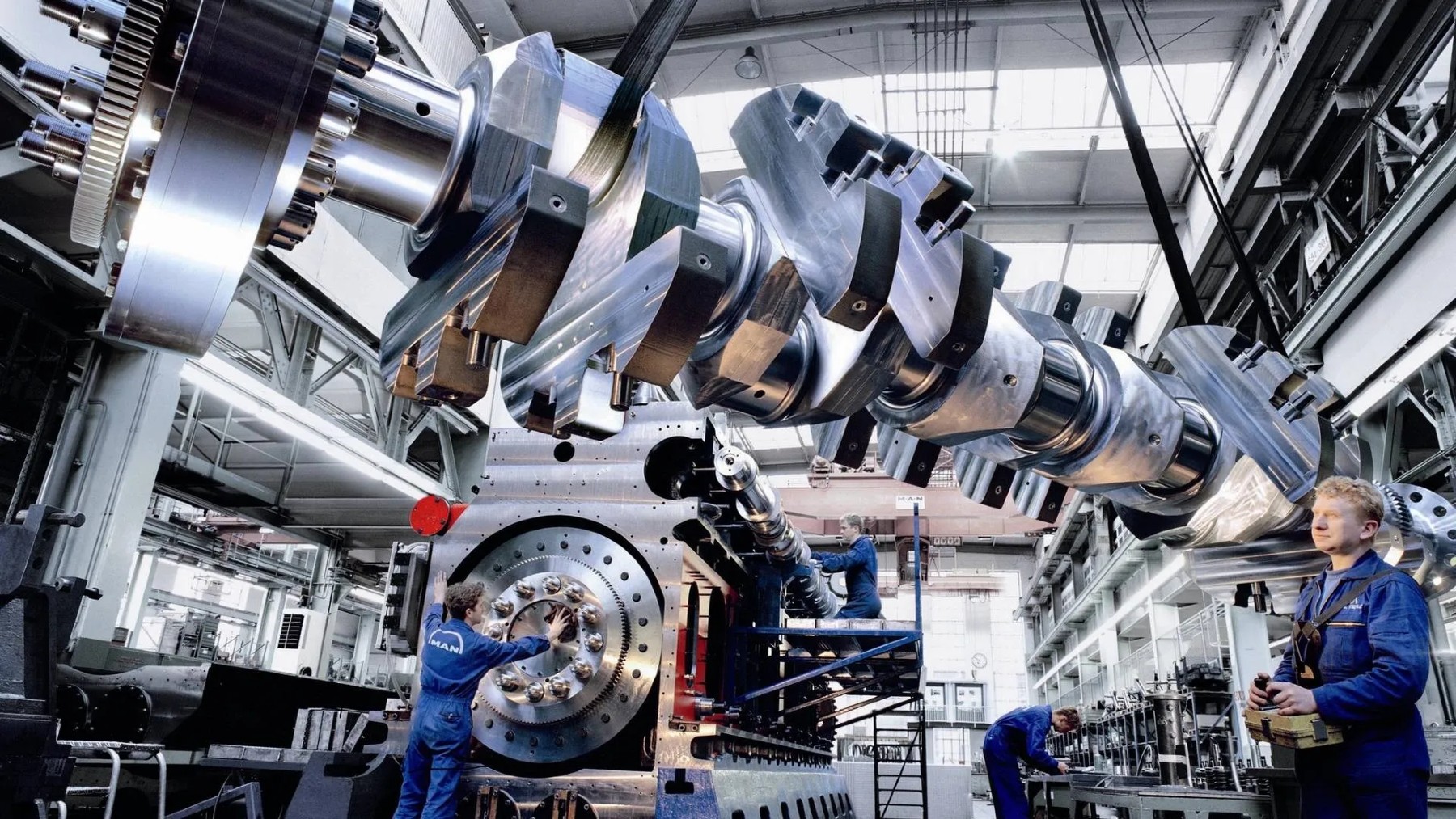

The work done by researchers at Sophia University to eventually reduce ammonia to be the sole fuel in the ignition process is centered around the intake system to improve the mixing of air with ammonia inside the engine cylinder in order to improve the efficiency of the internal combustion process. This work can be broken down into two overarching components: the fluid dynamics and storage capability.

By creating a vortex-like flow within the cylinder, the ammonia and air solution can be redirected into the cylinder to improve the combustion process during the intake and compression phase. Further, ammonia is much easier to store than hydrogen. By improving the practicality of the resource, the technology will be embraced more easily than if a working engine is produced but the logistics behind storing the fuel source are difficult.

Converting to sustainable solutions is a necessary push the world needs to embrace to achieve a sustainable future. Sophia University’s work is encouraging proof that the world is considering multiple options towards a green future using hydrogen.