Germany has managed to extract and purify nickel from low-grade ores in a single step by successfully making use of hydrogen plasma.

Although the world is focused on decarbonizing heavy industry, a stubborn challenge remains the production of core metals like nickel. Nickel has thus far been seen as a critical component for everything from electric vehicle batteries to wind turbines. However, the way nickel is produced has often come into question. Being produced via carbon-heavy processes, the strain falls on the environment and energy resources. For this reason, Germany’s achievement is considered to be groundbreaking. Perhaps this innovation may signify an entirely new era for sustainable metallurgy.

Something new in metallurgical history

For the first time in history, hydrogen plasma has been used in controlled, peer-reviewed settings to create ferronickel from lateritic ores. This entire process came about from the innovation of Isnaldi R. Souza Filho and his team at the Max Planck Institute for Sustainable Materials. Although hydrogen plasma has often been studied for ironmaking and theorized for other metals, it has never been seen as being effective for nickel. Nickel is generally classified as an especially stubborn element trapped in complex mineral matrices.

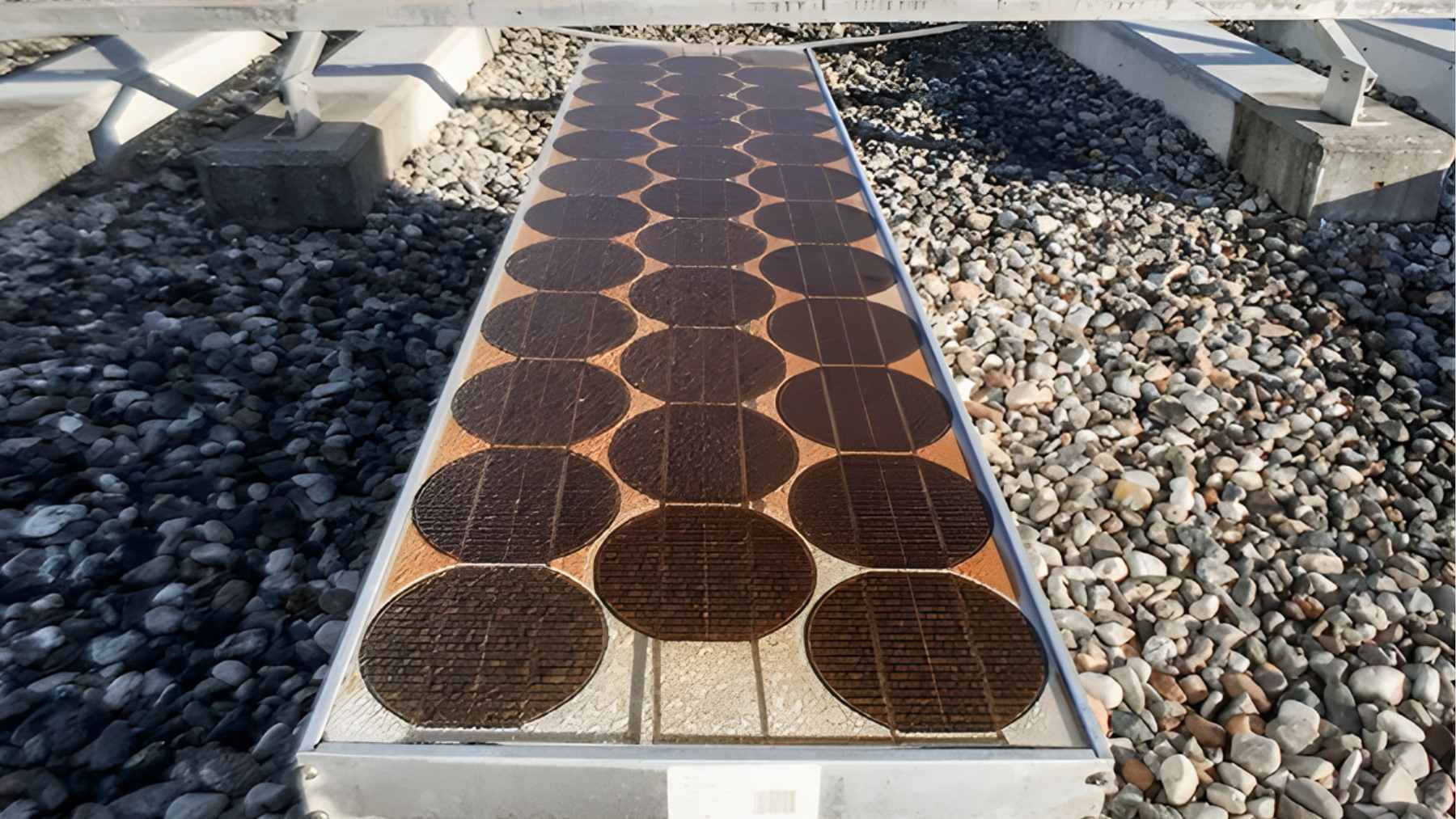

The team subjected a small batch of nickel ore pellets to a powerful electric current under a hydrogen-argon gas mixture using an electric arc furnace. What resulted was hydrogen plasma, which is considered to be a highly reactive mix of charged particles that can drastically reduce the metal oxides into a useful ferronickel alloy within only a few minutes.

Such a historic achievement can be attributed to the one-step process: extraction and purification that occurs simultaneously, without any need for subsequent refining. More dated methods required multiple high-temperature and chemical-intensive stages that emitted vast amounts of CO₂. Thanks to Isnaldi R. Souza Filho and his team, a new pathway has been created to reduce nickel’s carbon footprint by approximately 84% when powered by renewable energy.

Generating clean metal from toxic sludge

It is a known fact that nickel’s demand will double globally by 2040 due to the growth of the battery sector. The problem is that at present, high-grade ores are dwindling forcing producers to depend on lower-grade ores that lead to pollution in the process. More traditional hydrometallurgical methods rely on heat, pressure, and vast quantities of sulfuric acid and the pyrometallurgical techniques burn carbon-based fuels at 1600 ºC, releasing around 20 tons of CO₂ per ton of nickel produced.

With the use of the hydrogen plasma method, these emissions do not exist. The process is a simplified one that avoids fossil fuels. The Max Planck team was able to produce ferronickel with 20–40% nickel content that seemed to be on par with standard industry outputs with little impurities like phosphorus and silicon. As such, it can go directly into steel production without extra refining.

Deciding on commercialization

The challenge is that the reaction occurs at the interface between the plasma arc and the molten ore, and as such, scaling the process will require careful control of material flow to maintain consistent contact. Another challenge is that since hydrogen plasma itself is clean, the sustainability of the process depends on the use of green hydrogen, which is currently more expensive than fossil-derived alternatives.

While there are hurdles, the Max Planck researchers are confident in the technology’s long-term viability. A larger-scale reactor is already in the works, and the economic case for hydrogen plasma becomes increasingly compelling as green hydrogen and renewable electricity become more affordable.

1,000,000ºC and infinite energy

At the core of this innovation is hydrogen plasma, which is an exotic, high-energy state of matter rarely seen outside of fusion experiment. In the electric arc furnace, hydrogen is heated to over 1,000,000 ºC, transforming it into a seething plasma of ions, electrons, and atoms. This extreme energy unlocks reactions that conventional chemistry cannot match, enabling near-instant reduction of metal oxides.

Already researchers are looking into the discovery of a new color of hydrogen so exploring hydrogen plasma more thoroughly could yield amazing results, Hydrogen plasma could be the future promise of infinite energy.