Australia is the world’s leading supplier of iron ore, an industry that has become the foundation of its economy. However, emission reduction policies for all industries are advancing and becoming increasingly restrictive. It is for this reason that they are preparing to switch to green iron by 2028, a type of material that is neutral in CO2 emissions with new type of energy.

Australia is making its way towards decarbonization: they will be the pioneers in green iron production

Australia’s iron industry is one of the pillars of its economy, supplying the world’s major industrial powers such as Japan, China and Korea. By 2023, the production of this material reached 917 million tons and is still growing. However, to this figure must be added millions of tons of CO2 that are released into the environment.

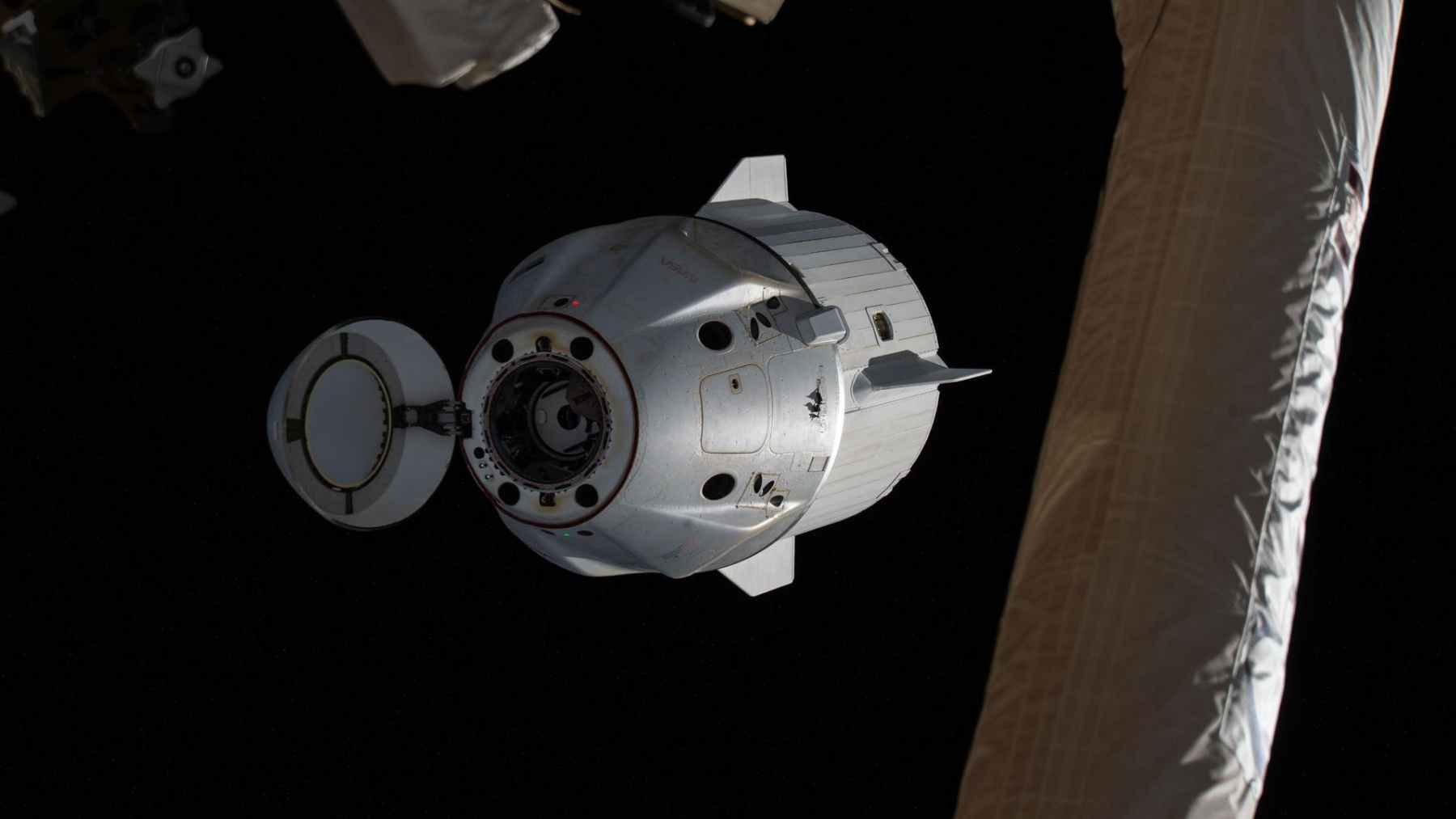

At present, there is a strong advance in the use of green hydrogen as fuel, being Spain one of the main drivers of this revolution thanks to an important infrastructure for green hydrogen production that would start to be operational around 2030. This fuel would start to be implemented in all industries to reduce emissions.

Against this backdrop, and considering the increasingly restrictive regulations for the generation of pollution in different industries, Australia is in an urgent need to switch its production to the new green iron. For this, they are preparing a series of incentives for major iron ore producing companies to start the production of direct reduction iron (DRI) with hydrogen.

The mysterious green iron that Australia will start manufacturing: What is it all about?

The mining industry is one of the strengths of the Australian economy, yet it generates around 60 million tons of CO2 per year during the extraction process alone. This could be a major obstacle in the economy of the future, which will be marked by increasingly stringent regulations for polluters.

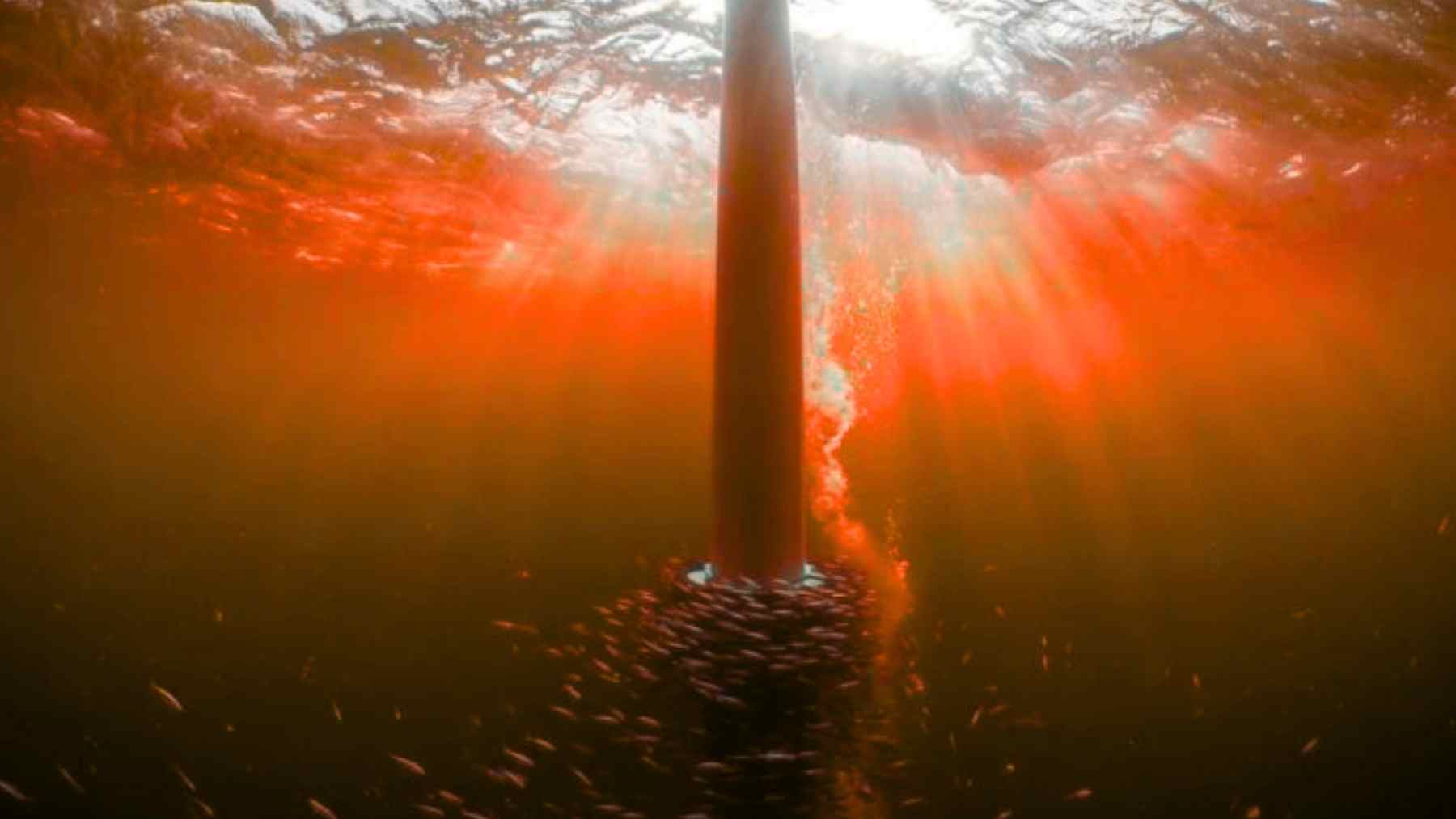

To produce high quality iron suitable for export, a process known as reduction is necessary. This is used to produce carbon monoxide, which is incorporated into the ore mixture with other substances, converting iron oxide into iron ore. In this way a high quality material known as DRI is obtained.

Natural gas is commonly used for the reduction process. The latter would be replaced by hydrogen to produce a material known as green iron, which is a DRI that does not generate CO2 during reduction. For this, the government has launched the Future Made in Australia initiative which, through the Hydrogen Headstart program, will fund green iron projects.

Australia’s new million-dollar projects: a strong bet for the iron ore industry

The Hydrogen Headstart program will offer an incentive of two Australian dollars for each kilogram of green iron produced by local companies. In this way, they will be able to maintain their presence in the market after the implementation of CO2 emission restriction measures such as the CBAM, the carbon emission adjustment mechanism in force in the European Union.

One of the main candidates for the Hydrogen Headstart program is Quinnbrook Infrastructure Partners’ green iron project, which is valued at about A$3.5 billion. It plans to use the green hydrogen produced at the plant near CQ-H2, although total emissions are still being studied to assess the project’s sustainability.

The whole world is switching to hydrogen

Hydrogen is fast becoming the key resource for the economies of the future. We will soon have the first hydrogen airport in America, while its application in other areas such as power generation, commercial vehicles and even shipping continues to be studied.