A new engine has just burst onto the global mobility scene, pushing EVs into the background and smashing the highly polluting traditional combustion engines (you know this already). The manufacturers, however, did not expect it to have ‘mutated’, and it now runs on a different fuel. If it originally used gas, everything has changed, and now it is much more efficient, renewable and environmentally friendly. The brand is well known, but now it has just skyrocketed in popularity thanks to an unexpected prototype.

This engine has “mutated” from gas to the first 100 % water fuel: INNIO Jenbancher has achieved the impossible

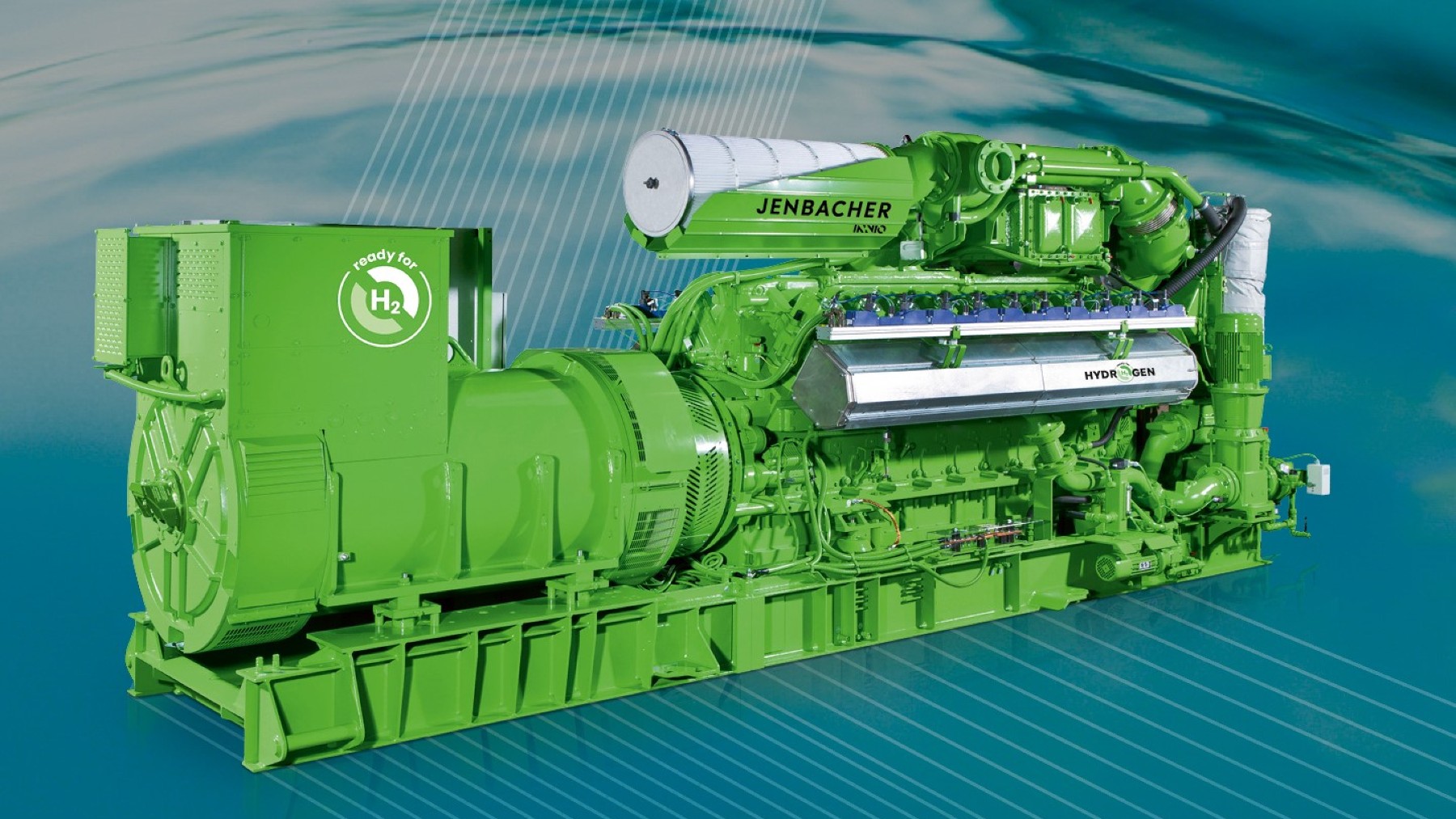

The company INNIO Jenbacher is a well-known producer of gas engine technology, and its transition towards engineering their engines to operate with hydrogen is a sign of a vital improvement towards future energy sources. In this change, INNIO is following the rest of the world in seeking cleaner energy solutions and its ability to adapt in light of changing energy environments.

Therefore, it is noteworthy that for many years, INNIO Jenbacher’s gas engines have been recognized as reliable and efficient. The company’s latest innovation, known as the ‘Ready for H2’ portfolio, also enhances such a reputation while tapping into the hydrogen fuel source. The most up-to-date technological improvement of the Jenbacher Type 4 gas engine is available, with an output of 500–900 kW.

These engines are intended to be flexibly designed with all kinds of applications in mind. They can work on pure hydrogen or a blend of natural gas and hydrogen, and this means that they can gradually be adopted with the increasing availability of hydrogen. This flexibility is needed in today’s energy market, where the transition to hydrogen is still in progress.

How to transform an engine from gas to hydrogen? INNIO is clear about the future of mobility

The engines incorporate several key design elements to accommodate hydrogen fuel:

- Modified combustion chambers.

- Upgraded fuel injection systems.

- Improved methods of fuel ignition and delivery of fuel-to-air mixtures in equal proportions.

- Components were enhanced in order to accommodate some of the properties of hydrogen.

- These modifications enable high efficiency and durability, particularly when operating on hydrogen or a mixture of hydrogen and natural gas.

What’s most promising about this new engine? Pay attention to its performance

While specific performance figures can vary depending on the exact model and operating conditions, INNIO Jenbacher’s hydrogen-ready engines demonstrate impressive capabilities:

- Efficiency: The engines effectively achieve high efficiency rates, thus becoming more competitive with other engines that use natural gas.

- Power Output: Depending on the fuel source, the Jenbacher Type 4 engines are capable of generating power between 500 and 900 kW when operating on hydrogen.

- Emissions: These engines are designed to run on 100% hydrogen, hence when they are running, they produce no CO2 emissions, and therefore the impact on the environment is largely reduced.

- Flexibility: These engines can be easily transitioned between operating on natural gas, hydrogen, or a combination of the two, thus providing desirable operating versatility.

INNIO not only transformed an engine: They have opened a new era in HICEVs

The transition to hydrogen operation for INNIO Jenbacher engines involves several key aspects:

- Fuel Flexibility: Today, all new models of the developed INNIO Jenbacher gas engines can be purchased with the “Ready for H2” package. This enabled them to operate on fuel blends of up to 25 percent hydrogen by volume in pipeline gas. The Type 4 engines take things a step further and are designed to be compatible with 100 % hydrogen.

- Conversion Process: The majority of the INNIA Jenbacher gas-fired power plant today installed can be retrofitted for the usage of up to 25% of hydrogen in pipeline gas or redesigned to run on 100% hydrogen. This conversion process typically involves:

- Changing the next fuel system to fit the hydrogen’s physical characteristics.

- Changing the control of the engine.

- It is possible to replace some of the components in order to guarantee the durability of the material with hydrogen fuel.

The new INNIO Jenbacher gas engine is a demonstration of the versatility of the prototypes of the future, something that even the brand did not expect. The fact that it runs on hydrogen opens the door, as you might now be thinking, to other legendary carmakers’ engines as well. Can you imagine Volkswagen’s engines emitting only water vapor? Actually, it has already happened with Tesla, though not officially, but with a group of engineers who set out to resurrect the old ‘Model S’ idea.