At first glance it looks like any other building site. Then you notice the silence. No hammering, no shouted instructions, just a robotic arm tracing wet concrete into neat curves. By the time most people are cooking dinner, that bare slab already looks like a house.

Scenes like this are spreading fast. Around the world, companies roll giant printers off flatbed trucks, load a digital file and let a robot pour a home layer by layer in less than a day. Pilot projects have already delivered 3D-printed neighborhoods in a fraction of the usual time and with far smaller crews than conventional builds.

Faster builds, smaller crews

Industry studies estimate that 3D-printed construction can cut labor needs by roughly 60% to 80% compared with traditional methods, since formwork and many repetitive tasks simply vanish.

Reviews also find that printing directly from computer models can reduce material waste by up to about 60% and speed up construction by around half. Less material on site means fewer dumpsters, fewer truck trips and shorter disruptions for neighbors.

For developers and city planners, that combination is powerful. Fewer delays, fewer accidents, more predictable schedules. On a spreadsheet, it looks like a clean win. For workers who used to frame walls or haul bricks on those same sites, it feels very different.

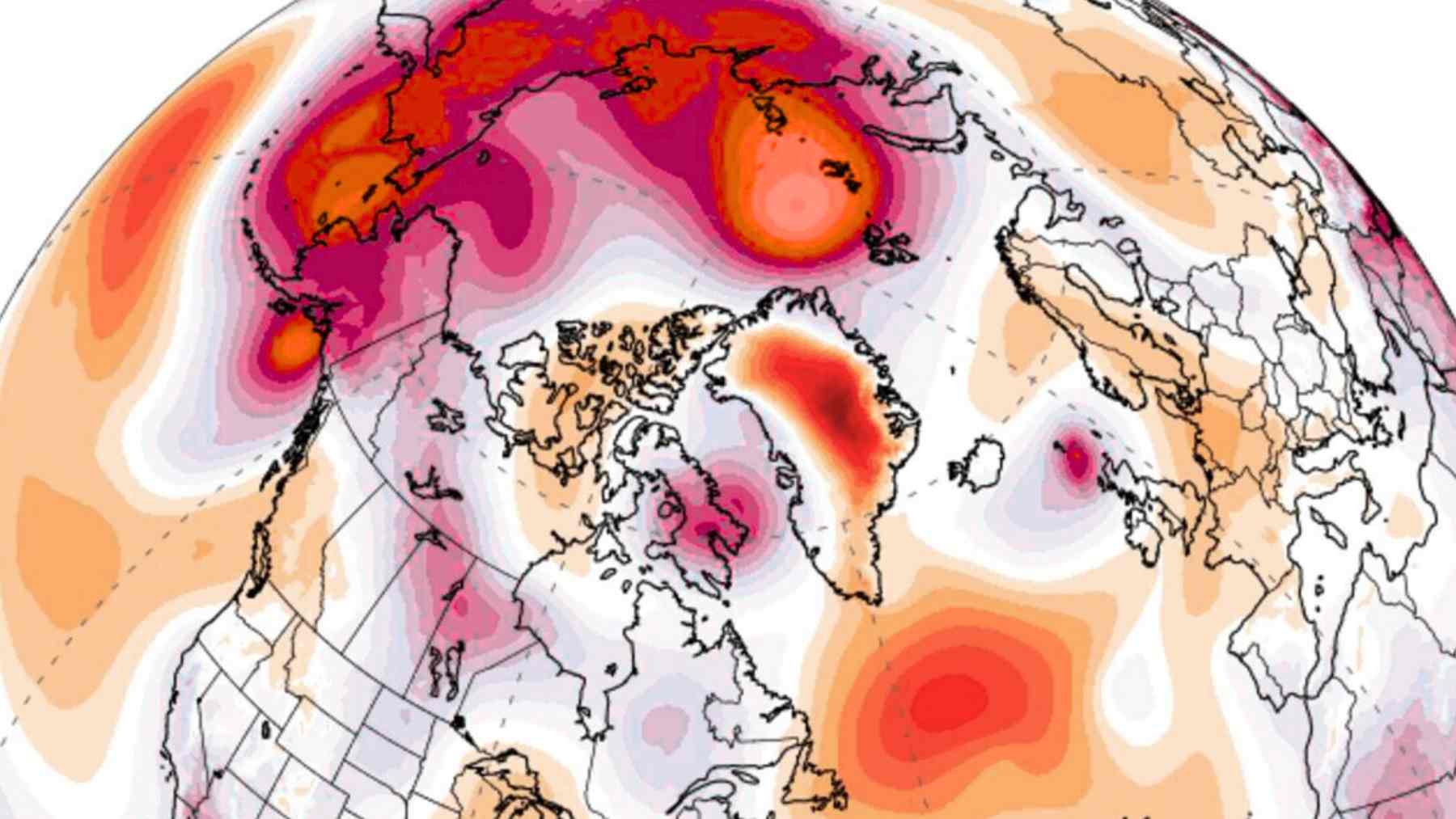

Why climate advocates care

The construction sector is among the biggest drivers of global carbon emissions, mostly due to cement, steel and the fuel that powers heavy equipment. That is why researchers are looking closely at house-sized printers.

A 2025 study in the journal Buildings found that 3D-printed housing can lower emissions by as much as 70% in some scenarios when geopolymers and recycled aggregates replace part of the cement, and still delivers savings even when standard concrete remains in the mix.

On the ground those percentages translate into everyday effects. Some new 3D-printed communities advertise thick insulated walls made with low-carbon concrete that can keep interiors cooler and trim electric bills in heatwaves.

Others are testing printers that extrude blends of soil, sand and natural fibers instead of cement, with early trials indicating that emissions per home can drop by about half while still meeting safety rules.

A greener home with fewer paychecks

There is a catch. The same machines that promise affordable, climate-friendly housing can quietly drain income from the communities they intend to help. When a printer delivers a long row of small houses in a low-income area, roofs go on faster and accident rates tend to fall.

Yet the stream of wages into the local economy also shrinks, because work that once supported bricklayers, carpenters and laborers is done by a handful of high-tech operators.

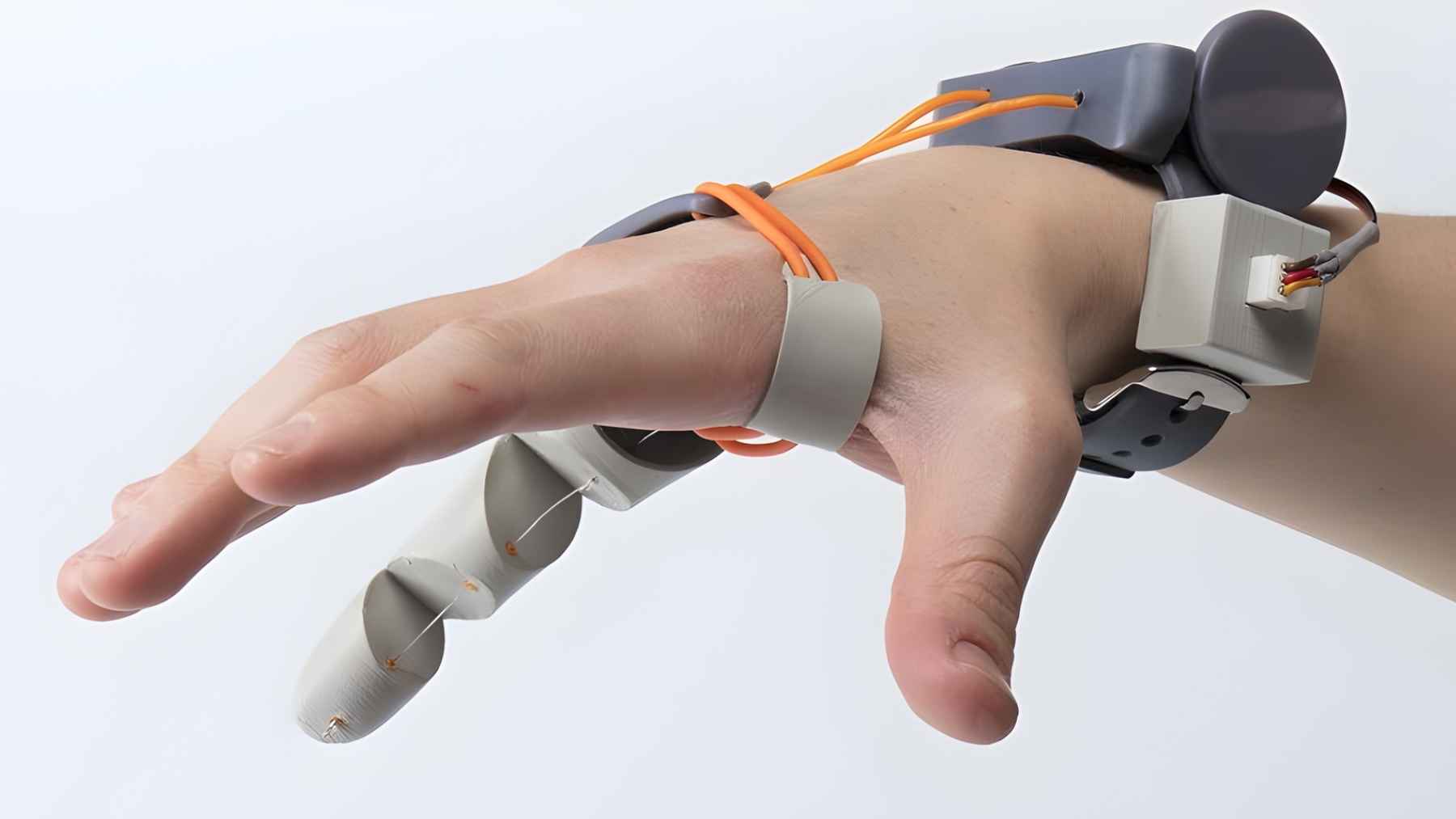

The divide is already visible on many pilot sites. Some workers stand at the fence, watching the robotic arm glide back and forth. Others are the ones holding the tablet, adjusting settings, loading software and resetting the pump when something clogs. As one construction manager in Copenhagen likes to tell crews, “Robots will not replace builders. Builders who work with robots will replace those who do not.”

Keeping workers in the story

For people who earn their living on site, the most realistic strategy is not to reject the printers, but to get as close as possible to them. That might mean learning basic computer-aided design, taking short courses on automated machinery or simply volunteering the next time a boss needs help setting up the printer. The feel for concrete and the instinct for a safe, solid wall do not become obsolete.

Public agencies can help connect the climate benefits to a fairer transition, for example by tying permits for 3D-printed housing to training funds or cooperative printer ownership. The ideas are not tidy yet, but they point toward lower emissions that also support local jobs.

The printers are arriving either way. The real choice is whether the next wave of 24-hour houses locks construction workers out of the story, or invites them in as the people who guide the machines that reshape our streets.

The study was published on MDPI.