Imagine a clear food bag strong enough to hold cherry tomatoes on the way home from the store, yet ready to dissolve harmlessly if it ever blows into the ocean. That is roughly what a team of scientists in Japan has just built, and it could mark a quiet turning point in the fight against microplastic pollution.

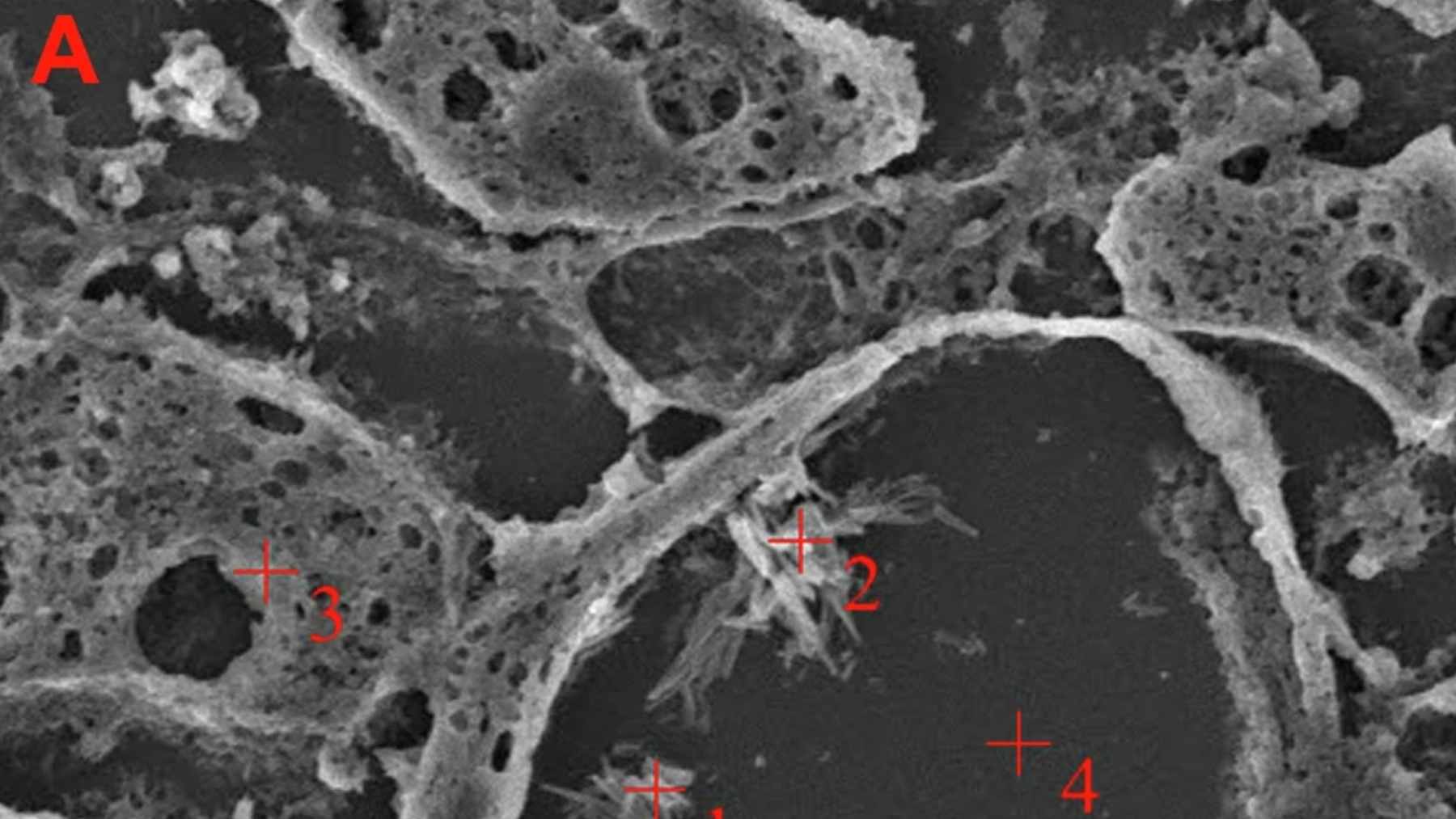

Researchers at the RIKEN Center for Emergent Matter Science and the University of Tokyo have created a new plastic made from plant cellulose that keeps its strength in everyday use yet breaks apart in seawater within a few hours. In lab tests, a small piece of the material disappeared in salt water after about an hour of stirring.

Biodegradable plastic that avoids microplastics

Unlike many products sold as biodegradable, this plastic does not slowly crumble into microplastics. Instead, when salt is present, it falls back into its original building blocks that common bacteria can digest.

The team reports that a piece a few centimeters across also disintegrates in salty soil after a little more than 200 hours, which is closer to days than decades.

Microplastic pollution in oceans and ecosystems

Why does that matter so much? Microplastics already contaminate almost every ecosystem that has been studied, from deep-sea mud to mountain snow. Tiny fragments have been detected in human tissue and even in the bloodstream.

At the same time, the UN Environment Programme warns that plastic pollution flowing into the oceans could roughly triple by 2040 to as much as 37 million metric tons every year.

Plant cellulose plastic and salt bridge chemistry

The Japanese group has been working toward this problem for several years. Their earlier experimental plastic also dissolved in seawater without leaving microplastics, but it was difficult to manufacture at scale.

The new version swaps in carboxymethyl cellulose, a biodegradable derivative of wood pulp that is already mass produced and approved by the United States Food and Drug Administration.

That cellulose chains up with a positively charged polymer that carries guanidinium ions, forming a tight network held together by so called salt bridges. When the material meets seawater, those bridges loosen and the network comes apart.

At first, that cellulose heavy plastic was crystal clear but almost as brittle as glass. To make it useful for real packaging, the team added a small organic salt called choline chloride, which is commonly used as a food additive.

By tweaking how much they added, the scientists could dial the film from hard and glassy to surprisingly stretchy. In some tests it could extend to about 130% of its original length without breaking, and still be processed into films as thin as about 0.07 millimeters.

Packaging innovation and sustainable materials

In practical terms, that means the same basic recipe can mimic different familiar plastics, from stiff clamshell packs to flexible wrap. Because all the ingredients are inexpensive, biodegradable, and already approved for contact with food, RIKEN argues that the material is well-placed for real-world use, especially in packaging.

Project leader Takuzo Aida notes that nature generates roughly one trillion tons of cellulose every year and adds that his group has turned this abundant resource into a flexible and tough plastic that safely decomposes in the ocean.

What still needs to happen for real-world use

There is still engineering work ahead. To stop a shopping bag from dissolving in a humid kitchen, the film needs a thin protective coating so it only falls apart under the much saltier conditions found in the sea. Coating methods are now the focus of ongoing tests, and the team has not announced a firm commercial launch date, although interest from the packaging sector is already strong.

For everyday life, this type of material points to a different way of thinking about plastics. Instead of assuming every wrapper and pouch will linger for centuries, designers can start to build in escape hatches. A snack bag that blows out of an overfilled trash can might not end up as bright flecks on a distant beach. It might simply vanish into molecules that microbes know what to do with.

Experts are careful to say that such innovations will not replace the need to cut single-use plastics, improve recycling, or strengthen waste collection. Yet a plastic that is strong on the shelf and weak in the ocean could, to a large extent, shrink the damage when things go wrong. As Aida put it in another interview, children cannot choose the planet they will live on, so scientists have a duty to leave them the best environment possible.

The press release was published on RIKEN.