Scientists at RMIT University in Australia developed a groundbreaking method to enhance hydrogen production rates through sound wave application. The innovative approach shows strong potential for transforming green hydrogen manufacturing operations to deliver better performance and lower costs. Researchers have shown evidence that sound waves play an essential role in improving hydrogen production, which brings potential global changes to clean energy operations.

A basic sound-wave implementation raises hydrogen production levels to 1400%

Ultra-high-frequency sound waves applied to water during the electrolysis procedure result in a 14-fold enhancement of hydrogen generation. Scientists published their breakthrough in Advanced Energy Materials that explainsкапacity of sound waves to boost electrolysis efficiency in water separation toward hydrogen and oxygen products. The application of 10MHz high-frequency vibrations within electrolysis methods promotes additional hydrogen liberation. The improved production benefits directly from this discovery, and substantial energy costs decrease.

By combining sound waves at 10MHz, the research team achieved an energy saving exceeding 27%, resulting in better sustainability and economic viability for the process. Such energy efficiency is a critical advancement for large-scale green hydrogen implementation. Through this research, scientists proved that basic physical forces can powerfully modify elaborate chemical reactions.

Sound vibrations make hydrogen production more economical because they can replace expensive electrode materials.

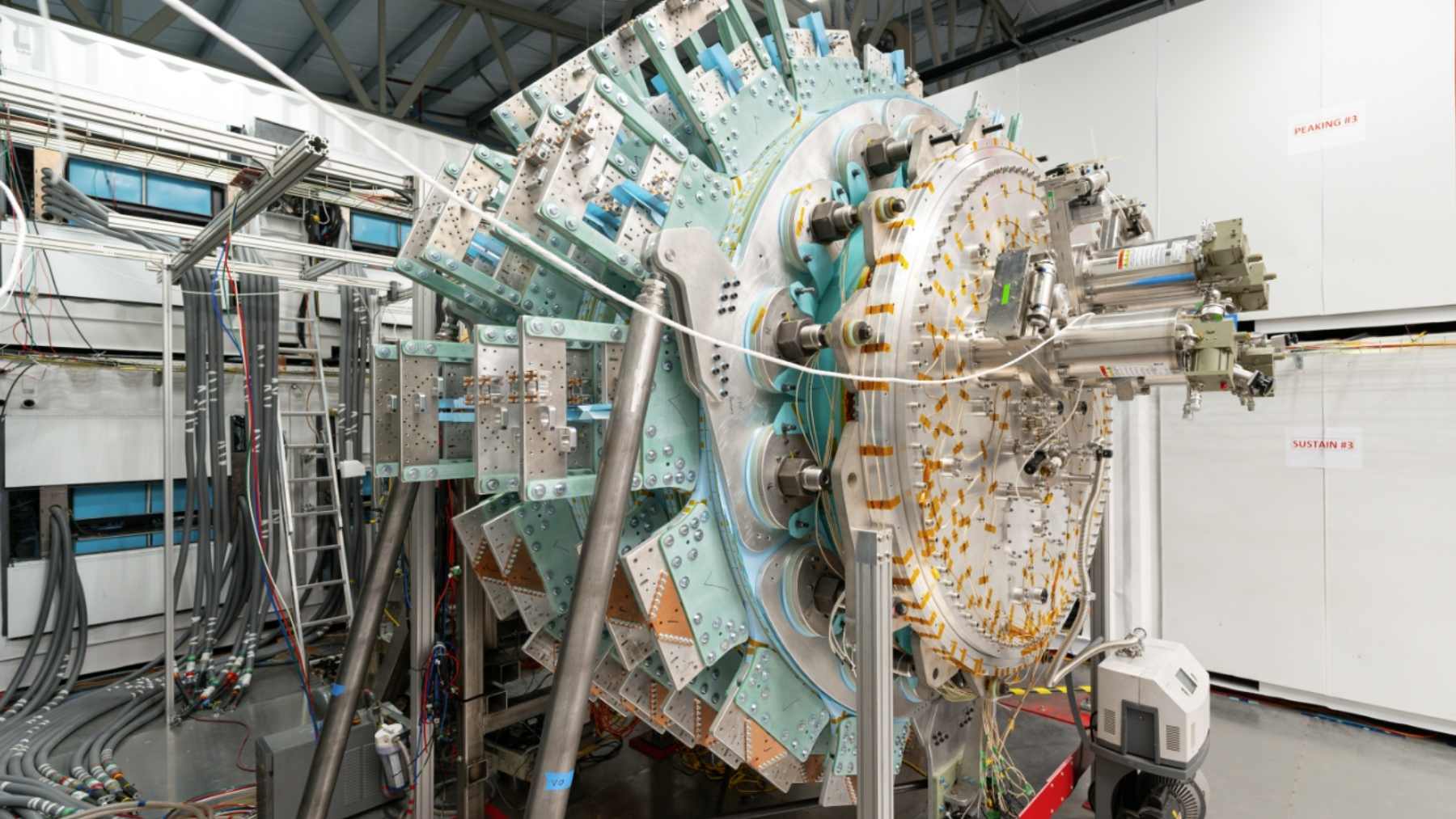

The production of hydrogen encounters substantial obstacles from electrode materials since platinum and iridium remain very expensive. The high price of these materials increases the total hydrogen production spending. The electrolysis process also benefits from utilizing sound waves to enable more affordable material selection.

Associate Professor Amgad Rezk from RMIT University’s School of Engineering demonstrated that sound waves make water hydrogen extraction simpler without using costly and corrosive electrolytes or electrodes. The adoption of silver material allows the process to become more financially viable due to its lower costs. The decreased material requirements turn green hydrogen production into a more accessible large-scale operation.

The development of sound waves creates a solution to prevent gas bubble blockages in hydrogen systems.

The use of sound waves enables the prevention of electrode surface accumulation of both hydrogen and oxygen bubbles. Traditional electrolysis operations have the issue of gas bubbles creating a layer that diminishes electrode functionality. The application of sound waves stopped electrode blocking, so their functionality stayed strong, and their operational duration extended. The innovation enhances electrolysis procedure efficiency while addressing bubble formation challenges on electrical components throughout various applications.

The researchers successfully obtained an Australian provisional patent for their technology, which demonstrates their intent to scale its applications. The research team needs to establish partnerships with industrial players to implement their sound-wave system into present electrolyzers. At its industrial scale, the technology has the power to change green hydrogen production standards, making it a sustainable option over fossil fuel usage.

Sound waves represent the future pathway for the hydrogen revolution to take place.

Sound waves demonstrate an exceptional capability to transform hydrogen production methods. This technology enhances the industry by boosting operational effectiveness, cutting expenses, and avoiding bubble formation to tackle critical production challenges. Innovations such as this will gain critical support from modern sustainability targets when the world transitions towards cleaner energy alternatives.

Scientists have made a major breakthrough by discovering that sound waves enable more efficient hydrogen production in green energy research. This innovative development demonstrates the potential to enhance hydrogen production, both efficiency and cost-effectiveness, leading to sustainable future possibilities. Advanced research into this technology shows great promise for hydrogen production because its application range expands into an era of modified hydrogen production methods.

The discovery enables opportunities for hydrogen production at locations with limited infrastructure and remote regions. Deploying modular sound-based electrolysis systems will enable off-line clean energy production at different local locations. The RMIT team foresees future achievements in acoustic engineering, which will enhance efficiency to a point where this method can scale up for international deployment.