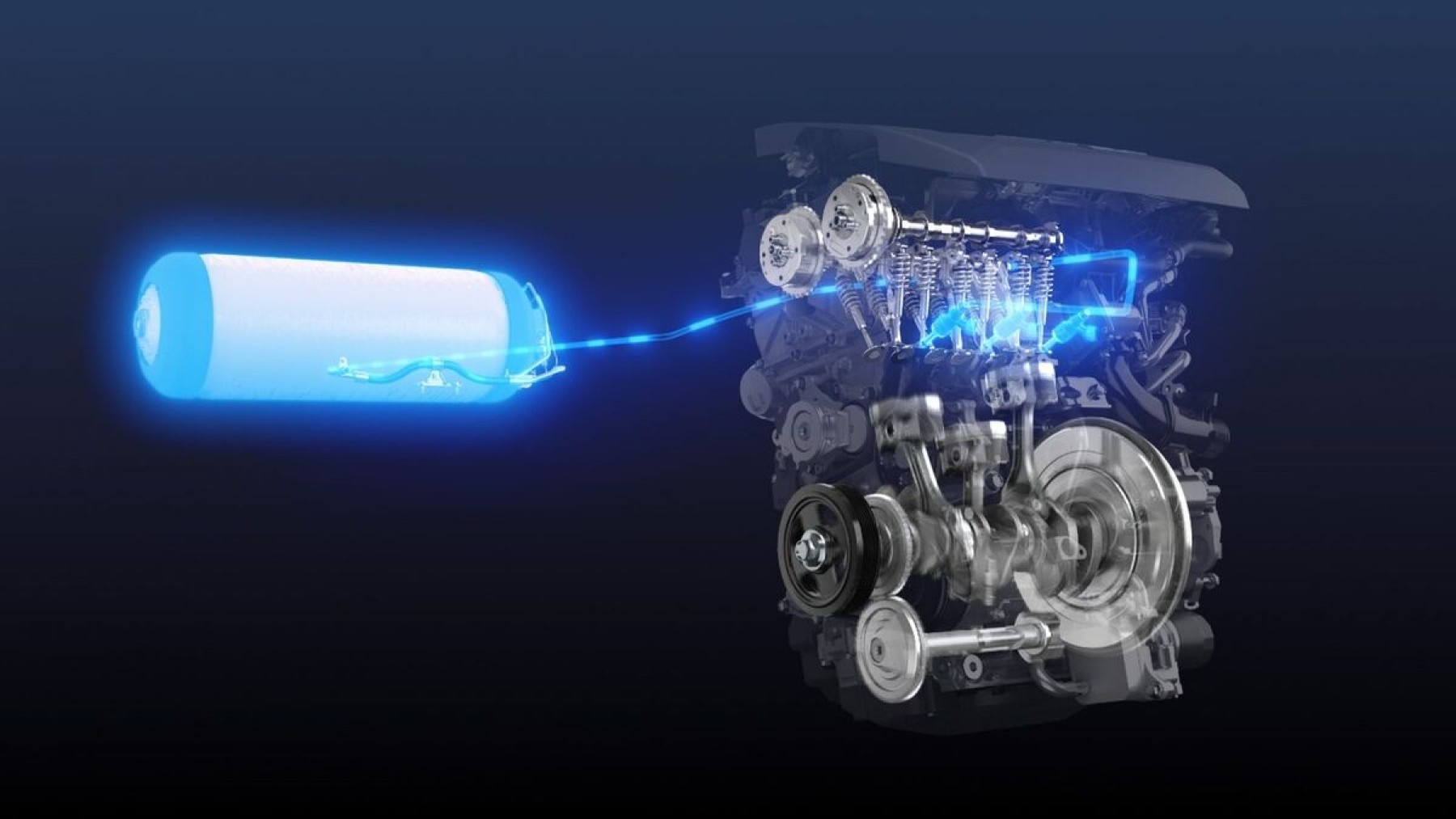

Currently, Toyota is exploring new possibilities for using hydrogen for vehicles with the help of its brand-new liquid hydrogen system. This novel system also features a self-pressurizer to counter one of the problems associated with hydrogen storage, namely boil-off gas loss.

If Toyota’s system can recycle the gas to make fuel in a similarly efficient manner, it could revolutionize hydrogen cars. This is a step toward the realization of the hydrogen vehicle that is more viable and efficient, which could revolutionize the automobile manufacturing industry.

How Toyota is overcoming the challenges of storing liquid hydrogen

The fact is that liquid hydrogen provides even greater density than gaseous one, which means that it is capable of storing more energy in the same volume. This makes liquid hydrogen a viable solution for long-range fuel cells.

However, storing hydrogen as a liquid is not without its problems, mainly boiling off, where the liquid hydrogen turns into gas. This escaping gas usually goes to the atmosphere, thus lowering the general fuel economy.

Toyota’s new self-pressurizer provides a way around this by trapping and recycling this boil-off gas and using it to fuel the vehicle without any extra energy. The self-pressurizer technology forms the core of Toyota’s new system of hybrid cars.

The core of this innovation is in the possibility of collecting boil-off gas that would otherwise be wasted and using compressive force to turn it into fuel. Toyota’s device uses the pressure of boil-off gas to build pressure inside the system and thus generate fuel without the need to add more energy.

This could completely change how hydrogen vehicles are charged, and it would mean that no amount of fuel would be consumed while in storage or during transportation. The system operates by passing the excess boil-off to a small fuel cell package, which drives the hydrogen pump motor, making the vehicle more efficient.

A technical breakthrough in overcoming hydrogen storage and pump challenges

A major problem with storing liquid hydrogen is the technical one, namely the low temperature at which hydrogen needs to be stored in the liquid state. Toyota’s system works at a very low temperature of -253 degrees Celsius during filling and storage. This makes the vehicle hydrogen pump system especially susceptible to failure, as hydrogen pumps are one of the most failure-prone items in hydrogen systems.

But Toyota’s self-pressurizer is useful not only for the problem of fuel waste but also contributes to improving the reliability of the hydrogen pump. The device is designed in a way that part of the cold energy is used to compress the boil-off gas, making the pump work easier, thus making it last long.

Expert insights: Toyota’s hydrogen vehicle experiment could shape the future

Dr. Jacob Leachman from Washington State University and an expert in hydrogen also endorsed the innovation adopted by Toyota while acknowledging that liquid hydrogen vehicles have always been tricky to design because of storage and pressure control.

He pointed out that hydrogen pumps are generally a weak link. Toyota’s use of cold energy derived from boil-off gas for compression might enhance the dependability and effectiveness of hydrogen systems going forward. According to Leachman, this discovery is crucial for anyone who is trying to design cold hydrogen vehicles, and it represents a major ‘next step.’

Toyota’s experiment with liquid hydrogen and the self-pressurizer is a big step forward in hydrogen vehicle development. Besides enhancing the efficiency of hydrogen cars, this system also provides a foundation for more extensive use of hydrogen as a green fuel. Thus, Toyota is not only staying loyal to hydrogen as a real energy source but also can significantly change the future of the automotive business.