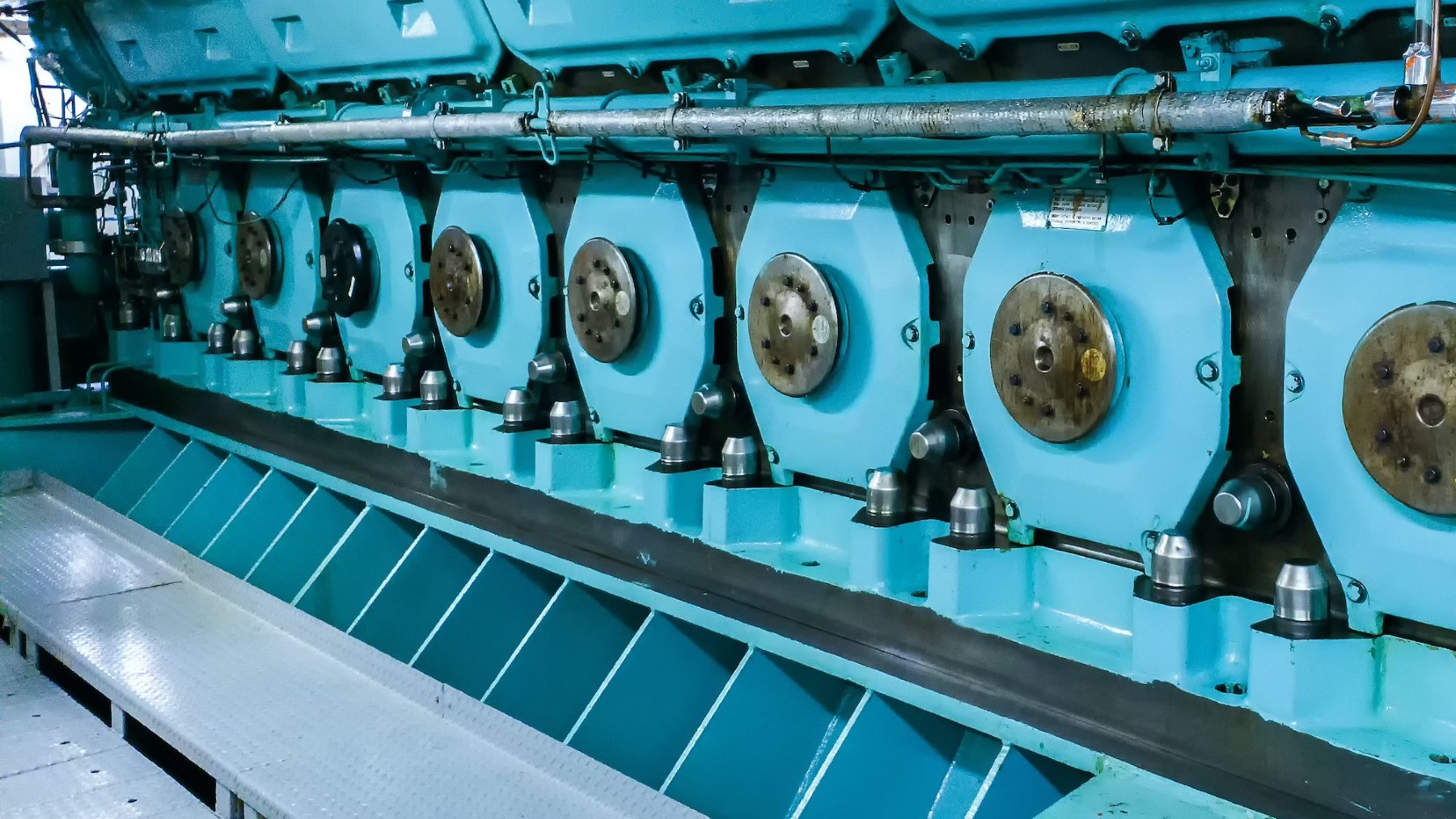

While electric vehicles seem to be taking something of a backseat with the possibility of hydrogen powered engines, MAN Energy Solutions is defying expectation by going in a completely different direction. The German manufacturer of diesel engines and turbomachinery announced earlier this year their plans to deliver the first engine fueled by ammonia. The engine will be installed on a vessel in Japan and ammonia-powered engines will be ready for MAN’s clients by 2027.

Ammonia can be generated by both fossil fuels and renewable energy sources

MAN’s announcement comes with other engine manufacturers plans to go green and search for alternative solutions to power automobiles and other machinery. The shipping industry currently takes responsibility for overseeing 90% of the world’s trade but also accounts for about 3% of the world’s carbon dioxide emissions. Green energy alternatives are thus an essential component to the future of vessel trading.

While ammonia is generally associated for being a product of fossil fuels (making the whole alternative energy point null), it can also be produced through renewable energy sources like wind or solar energy. When produced through sources such as these, ammonia has a net carbon footprint of essentially zero and will not emit any carbon dioxide, Sulphur Oxides, particulate matter, and unburned hydrocarbons during the combustion process.

The ship will take approximately two years to build and organize

Because the ship is the first of its kind, not only will it take at least two years to build and undergo trials but various unique logistic requirements will need to be planned out. New safety procedures need to be developed as well as fuel supply and bunkering infrastructure solutions need to be considered. Bunking refers to the process of ship refueling.

Cooperation between world port authorities will also need to be done. The ammonia bunkering process is significantly more dangerous than traditional fuel sources. Ammonia is toxic and not handled correctly can be a serious risk for death for ship refuelers. The safety element of actually building the ship will also be a challenge as it has never been done before so there are no existing guidelines to follow for how to carry the process out.

MAN’s biggest challenge will be the human element of the operation

MAN has recently made strong investment decisions regarding alternative energy. In March of this year, MAN opened a workshop in Singapore worth 20 million euros to maintain, repair, and retrofit fleets using their dual-fueled engines. These engines can burn both traditional fuel sources such as oil oil as well as alternative fuels such as liquefied natural gas and methanol.

While the aluminum powered ship remains in the works, MAN is concentrating their efforts to upgrade existing ships to take on these dual-fueled engine as the company embraces the necessity to go green. CEO Uwe Lauber says that the biggest challenge they are facing currently is not the development of a new engine from scratch, but rather addressing their existing fleets as customers do not want to discard their current ships.

Lauber estimates that of the 20,000 MAN ships which are currently in use globally, roughly 3,000-5,000 can be retrofitted to burn alternative fuels. The conversion process is estimated to cost the company between $25 million to $50 million. Not to mention the cost of producing entirely new ships with dual-fueled engines. Currently, MAN ships use 30% biofuels which the company is wanting to up to 100%.

While the shift to go green is in no way going to come cheap, it is an investment for the health of our planet. Slowly shifting reliance to alternative fuel sources is no longer an option but something all industry must adapt towards.