One of the world’s most unusual and contradictory mining sites exists below Salt Lake City’s surface in Utah. The Bingham Canyon Mine occupies 95,000 acres, becoming the Earth’s largest artificial hole that actively keeps extracting copper from massive mineral reservoirs while environmental issues rise.

How an American community rose to occupy the hole containing the world’s most significant mineral value

The vast underground mining structure achieves its position as “the richest hole on Earth” through dimensions of 2.5 miles in width and 0.75 miles in depth. For 2021, the Getchell mining site produced 159,400 tons of copper combined with 139,500 ounces of gold and 2.22 million ounces of silver. Modern technological developments depend on the essential mineral components, including molybdenum and tellurium, that are located beside valuable copper and other metals within the site.

This site stands out among all American mines due to its features

The Kennecott copper project, run by Rio Tinto, sustains over 2000 employees while it operates with leading-edge mining technology. Development at the operation relies on substantial drilling apparatus, intelligent blasting technology, and massive trucks that move 218 tons at a time. The gigantic dimensions of this mining operation reach a point where astronauts from space can observe its brilliance, demonstrating human engineering mastery.

Mining workers continue going underground because of an unexplained luminescence effect

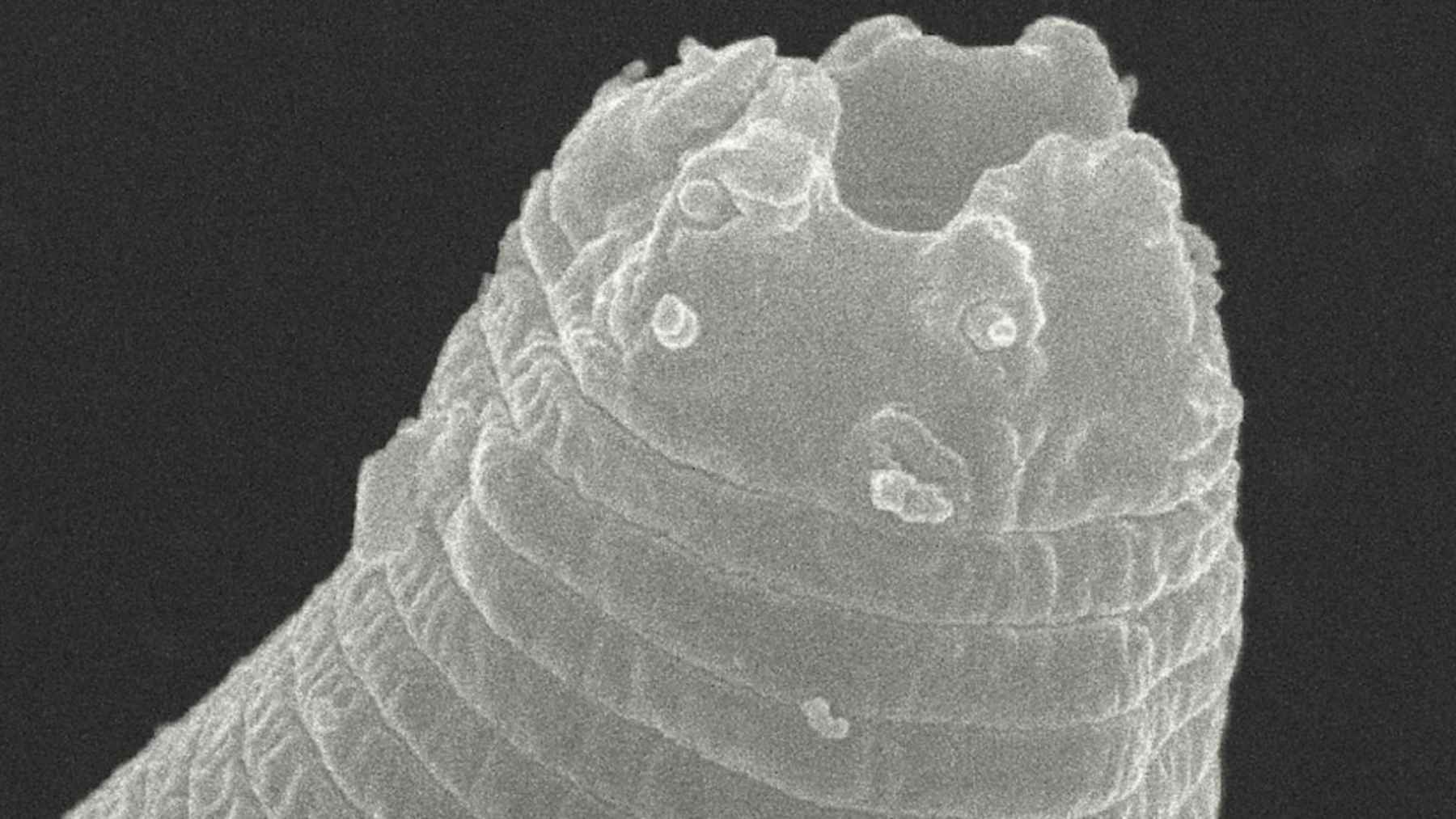

CGRectGetMines continues to increase its operations because the site contains exceptional mineral resources, regardless of environmental issues. The mine contains 2.11 million tons of copper, 2.09 million ounces of gold, and 28.52 million ounces of silver as its proven and probable mineral deposits. The high concentration of valuable minerals transforms specific locations within the mine into a magical scene that earned the spot a mysterious reputation.

Experts studied the hidden mystery of this town’s mysterious glowing phenomenon

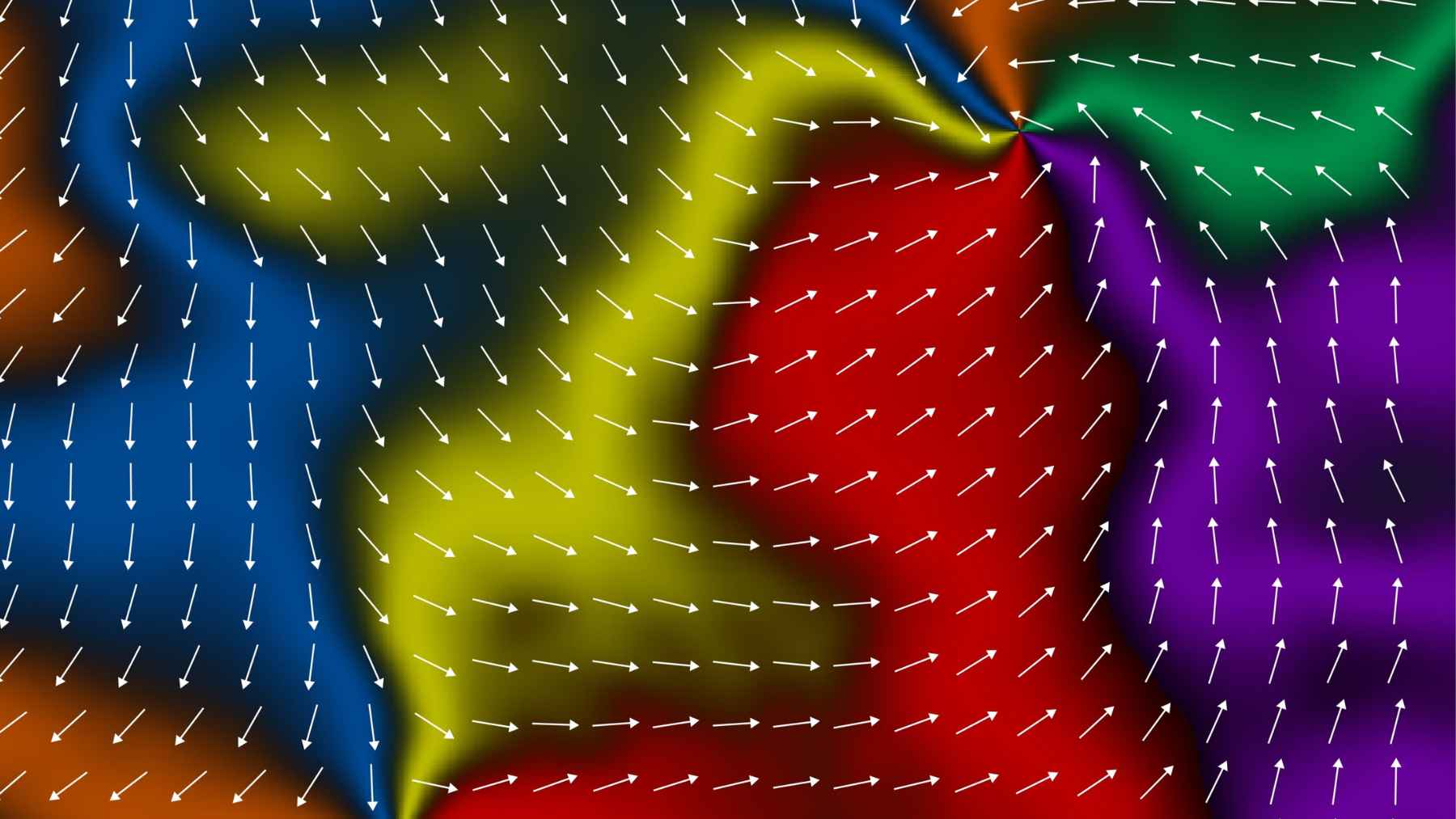

Geological analysis of the mine shows a consistent sulphide mineral distribution as chalcopyrite, which fits the classification of a copper porphyry orebody. A total of 20 million tons of underground minerals exist, which contain outstanding levels of 3.65% copper and 1.62g/t gold. Miners maintain their activities because of the present mineral levels in the ground.

The environmental concerns do not stop this hole from further development

The mining facilities at Bingham Canyon have grown in size as environmental concerns continue to rise. The massive water requirements and high energy needs do not diminish the mine’s essential role in Utah business operations and worldwide commerce. The Copperton concentrator handles tons of ore daily using the biggest SAG and ball mills worldwide.

Everyone remains concerned about the fate that this town faces in the future

The mining organization has established operational targets that will continue until 2032 after conducting persistent research for further resource discovery. The company continues its investigations into underground resource opportunities by adjusting the location of its North Wall boundary. The company maintains its aggressive operational expansion despite ecological issues because economic demands face off against environmental obligations.

The Bingham Canyon Mine facility demonstrates both human technological skills and our contradictory approach to natural resource usage. Although Bingham Canyon Mine delivers key resources for technology development and economic growth, it poses significant environmental issues regarding sustainability. The expanding depth of the mining operation presents enduring questions about how human resource extraction and ecological protection will balance for future generations.

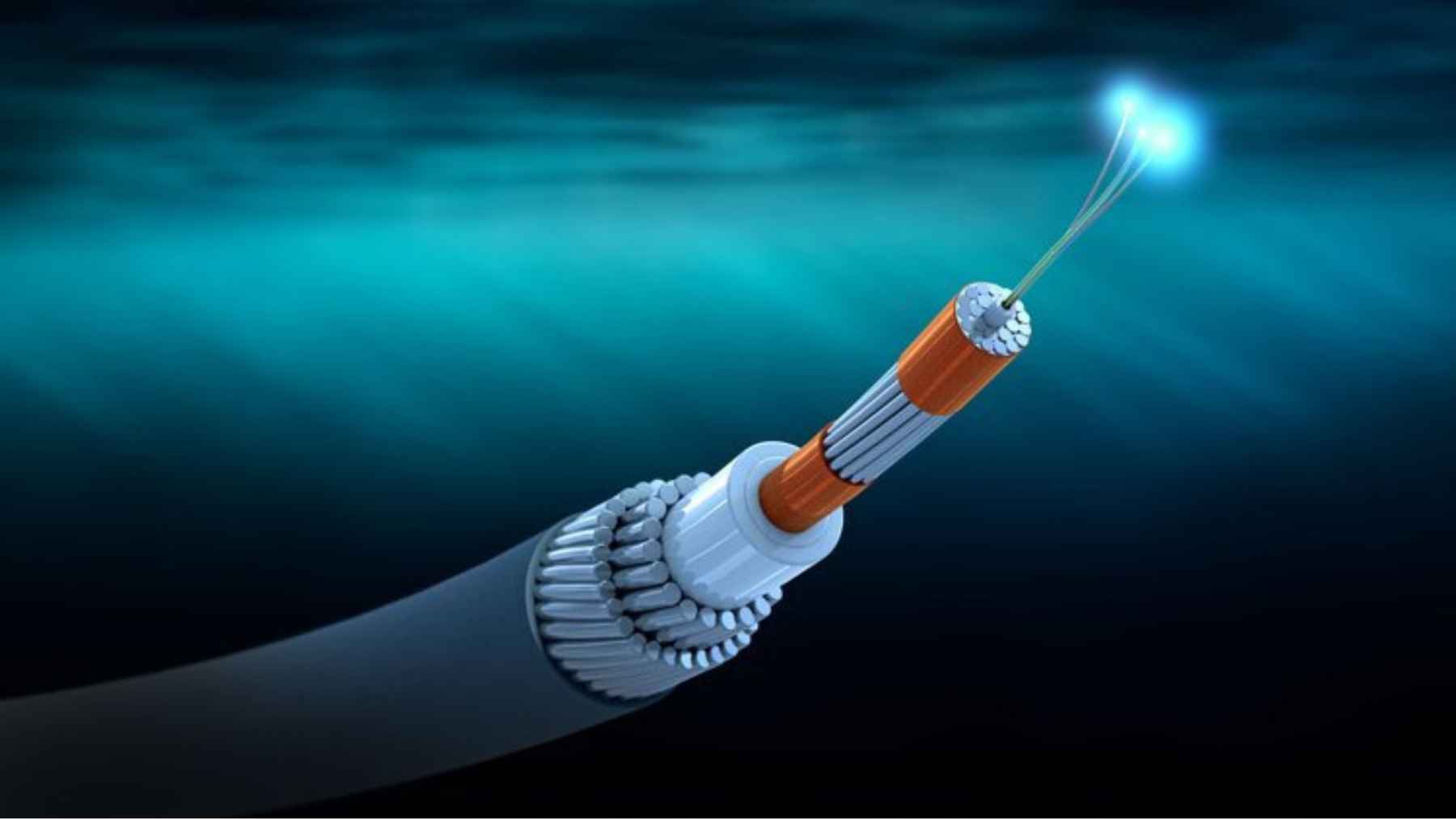

The facility at the mining site runs four connected lines that grind materials before floating them to extract copper and molybdenum concentrates. The smelter uses flash smelting technology to process copper concentrate delivered from the mining facility by pipelines for 27 kilometers until generating 98.6% pure copper and completing final refining stages to reach 99.5% purity. While powerful, the industrial establishment requires large energy consumption and prolonged construction activities. This operation delivers inevitable economic advantages because it ranks as one of the world’s largest technologically superior integrated copper complexes.