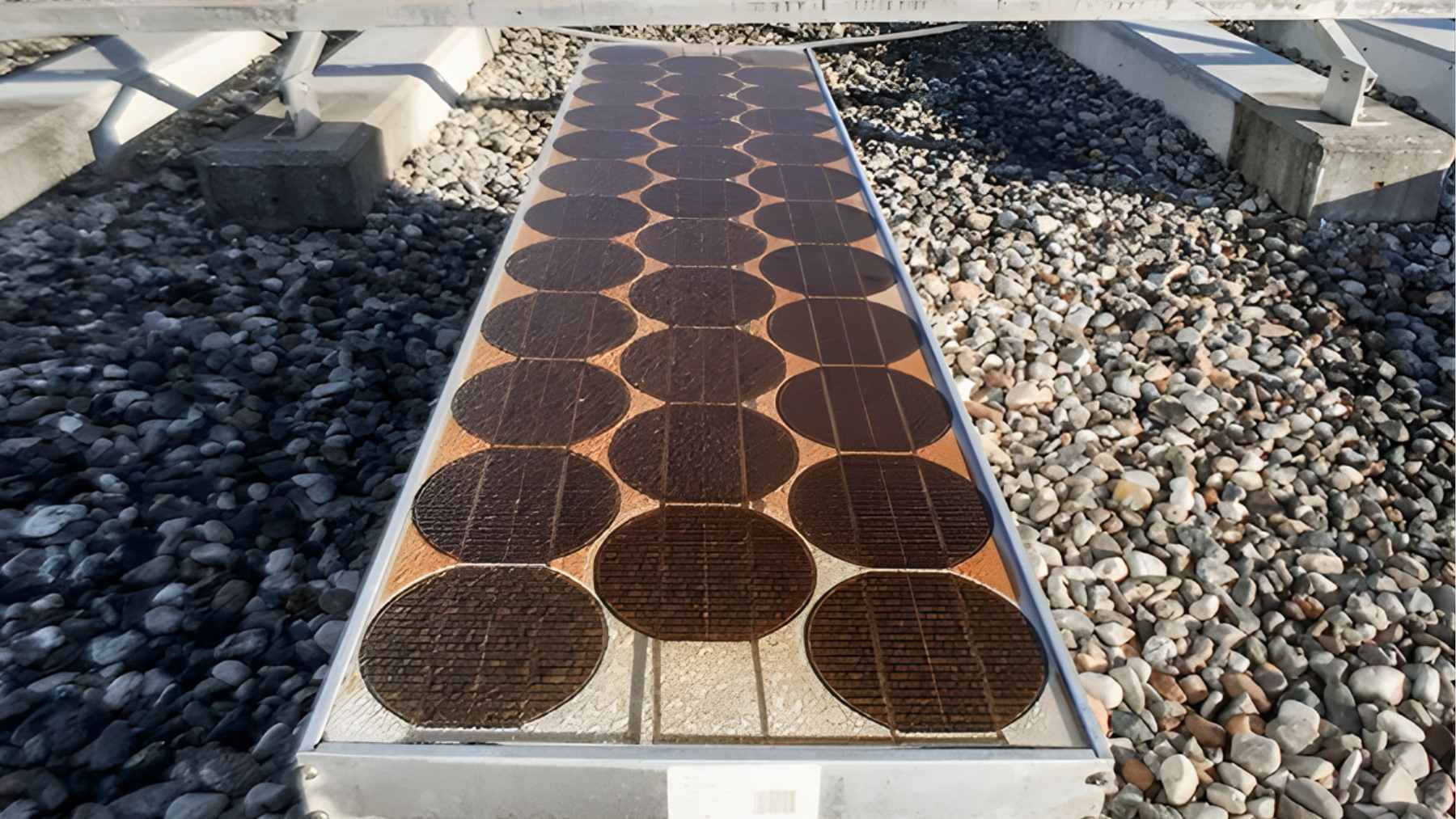

We welcome an era of solar energy no longer dominated by traditional silicon-based photovoltaics. As such, a new generation of solar cells is making its way to the center stage based on a specific type of material. Tracing the roots of how harnessing solar power began to take shape leads us to look deeper into American inventor Charles Fritts, who was responsible for the first working solar panel using selenium wafers coated with a thin layer of gold. The creation by Fritts was not effective, however, it opened the doors to the possibility of unlocking the sun’s powers.

The discovery of an alternative to traditional panels

At the very core of this discovery is a team from the University of Rennes and the Shenzhen University who created a passivation technique to improve the performance of the material that tosses the idea of using traditional silicon-based panels out the window. What the researchers did was heat-treat the CdS/CZTS heterojunction (a linkage between the absorber and buffer layer) in a rather oxygen-rich environment. In this way, the researchers succeeded in addressing all the main setbacks of sulfur vacancies (VS)- the primary sources of charge recombination.

During processes that occupy such vacancies, oxygen atoms are introduced to heal the defects. Treatment, as such, fosters the diffusion of cadmium ions and the formation of Na–O and Sn–O complexes, thus reducing defects, ensuring energy conversion becomes more favorable.

All in all, the certified efficiency of 11,51% is achieved, which is quite the milestone. An entirely new chapter in solar technology has been penned with one specific material being at the forefront.

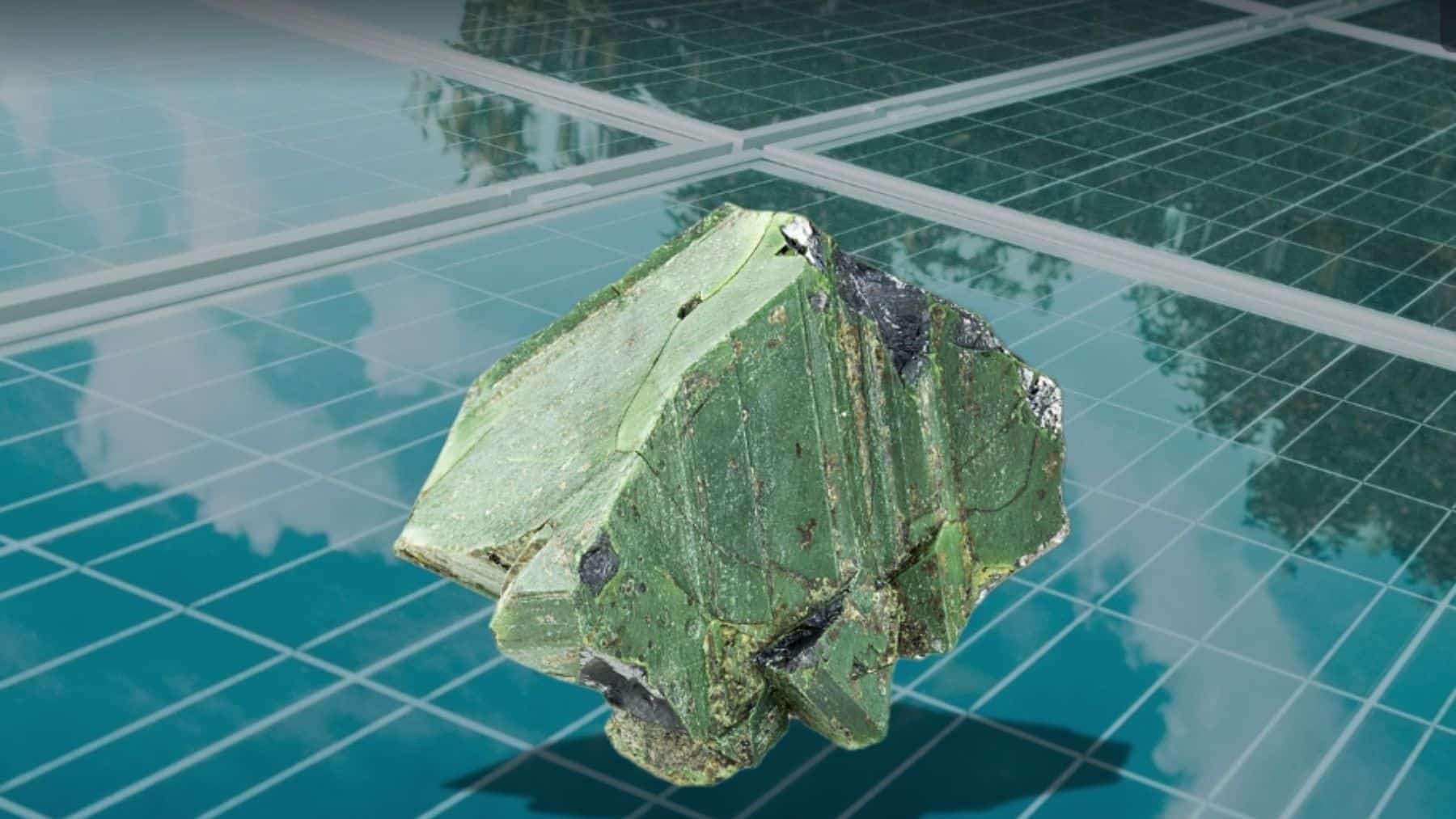

The greener alternative: Kesterite

It is not only researchers from the University of Rennes and Shenzhen University who studied kesterite in terms of solar panels. Researchers at the University of New South Wales (UNSW) in Australia also considered this material with success. The use of kesterite shows that solar cell technology is evolving. From selenium to silicon. With many silicon panels now accounting for the majority of solar installations worldwide, silicon-based panels are the way to go. However, the production of these silicon panels is resource-heavy and works with high temperatures and toxic chemicals. This fact about silicon caused researchers to explore alternate materials, perhaps not as efficient but more sustainable and cheaper.

Cu₂ZnSnS₄ (CZTS) or Kesterite is a strong contender in the solar energy game. It is an abundant and non-toxic element that has proven to be cheaper and far more environmentally friendly in comparison to silicon. Kesterite is best for use in multijunction solar cells, focused on layering the different materials to capture more of the sun’s rays.

Kesterite has long been overlooked as a material of choice due to its flaw of low power conversion efficiencies (PCEs). The cause of this problem is atomic-scale defects that trap charge carriers, provoking energy loss through non-radiative recombination. A setback that has been holding researchers back may no longer pose a challenge.

An achievement in solar power

This is perhaps the most significant moment in Solar’s history after the discovery of Fritts’ first solar panel in 1883. We are saying goodbye to photovoltaics and embracing the reality that while silicon solar panels dominated the solar market, cleaner and newer alternatives can be brought to the forefront.

Being a non-toxic substance found in abundance, the appeal of Kesterite cannot be doubted. Having the potential to integrate into multijunction cells could lead the way for better efficiencies in the future. If Kesterite has now become the frontrunner in the solar game, 2025 may be the year that solar power got refined 140 years or so after Charles Fritts shed light on solar power and what it could mean for us. The end of silicon solar panels is officially here.