Researchers at the University of Illinois, Chicago (UIC) created a revolutionary fusion process between hydrogen and nitrogen that offers significant potential to change the production of ammonia and hydrogen fuel. However, the promising combination produces disastrous effects. This article explores the important breakthrough regarding a fusion reaction between hydrogen and nitrogen while examining its probable results.

A new method for hydrogen production

Solar power and agricultural waste

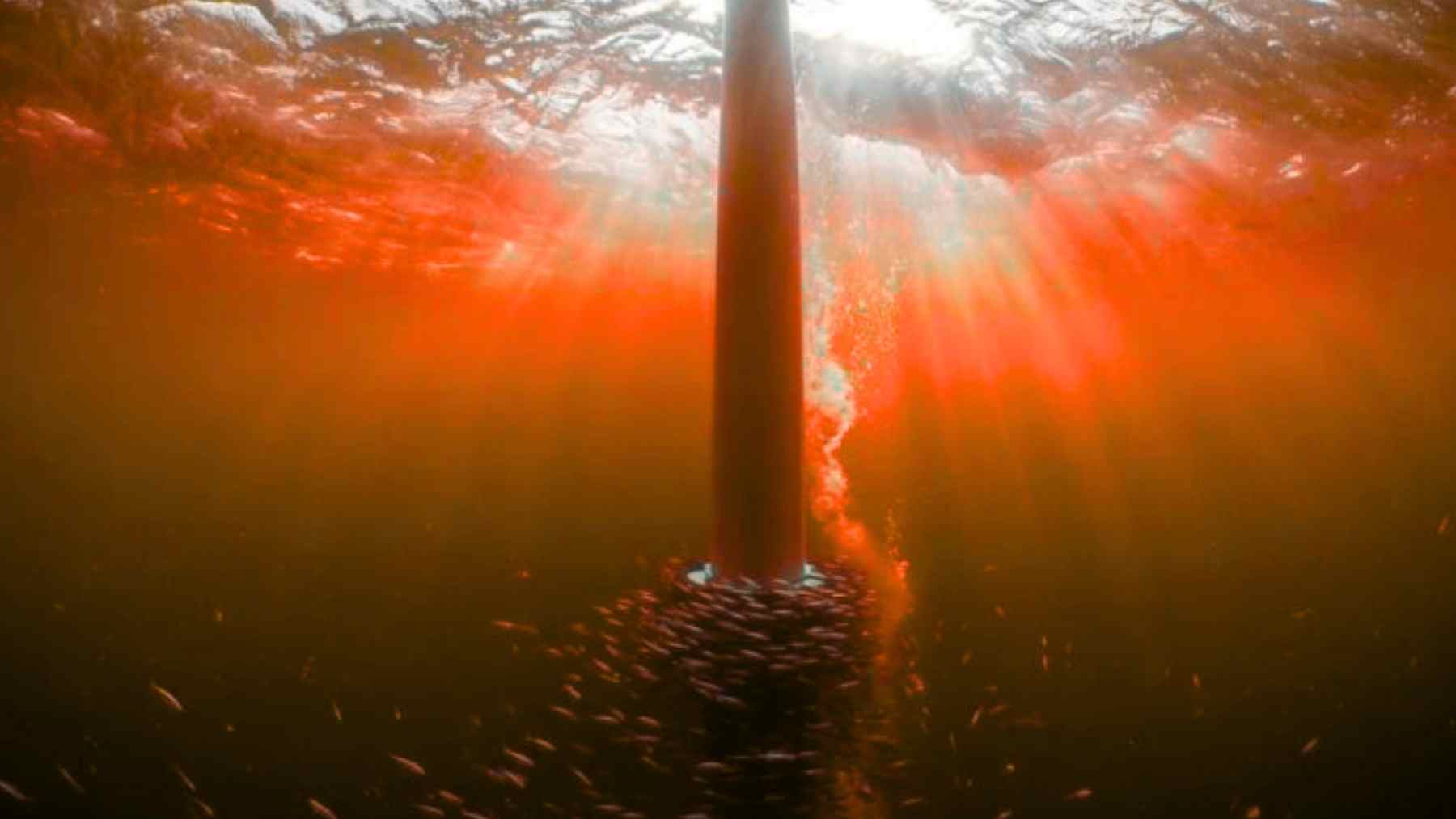

UIC engineers designed a special technique to derive hydrogen gas from water through solar power and farm commodities. This innovative approach cuts the energy required for water hydrogen extraction by 600% to establish a sustainable hydrogremaking method. Biochar extracted from agricultural waste is a carbon-heavy material that reduces electrical consumption during water splitting operations.

The innovative method increases hydrogen production efficiency and relies on renewable energy through solar power. The integration of biochar derived from waste products, including cow manure and sugarcane husks, increases the method’s sustainability.

Efficiency and environmental impact

Tests demonstrate that the method effectively produces nearly 35% hydrogen from biochar in combination with solar energy. The method reaches high efficiency using electrical power that measures less than what AA batteries produce. As part of the process, the generated carbon dioxide is collected through carbon capture systems that allow its use for beverage carbonation and chemical production for plastic manufacturing.

The discovery opens opportunities for farmers to generate their power needs independently while establishing new sources of income. Clean hydrogen production gets an encouraging new option because it operates with low energy needs and waste resources.

Cleaner ammonia production

Lithium-mediated synthesis

UIC engineers introduced the removal of hazardous effects from the ammonia production process by developing a lithium-mediated ammonia synthesis methodology. A combination of nitrogen gas and hydrogen-donating fluid occurs while a charged lithium electrode is used. Lithium-Mediated Synthesis works at low temperatures under regenerative conditions compared to standard high-pressure high-temperature methods.

This lithium-mediated method operates efficiently with excellent selectivity to fulfill Department of Energy requirements for industrial production. It produces ammonia for $450 per ton, 60% less expensive than past methods.

Potential for hydrogen fuel

The new ammonia production technology reveals future possibilities for using it as a carrier of hydrogen fuel. Through its carrier role with ammonia, hydrogen transport becomes less expensive and safer. The destination facilities convert ammonia into hydrogen, which represents a viable method for the distribution of hydrogen fuel.

The proposed method simultaneously produces environmentally friendly ammonia while offering efficient hydrogen fuel shipment to reduce overall carbon emissions from these vital materials.

Environmental concerns

The combination of hydrogen and nitrogen brings various advantages, but it creates severe destructive outcomes, which some may describe as potentially catastrophic. Clean ammonia production coupled with hydrogen creation requires the generation of carbon dioxide as a byproduct. This production waste receives systematic recovery attempts despite environmental concerns about its possible impact.

Massive hydrogen/ammonia production would result in lower carbon emissions, except when executed without adequate management. Developing thorough strategies remains essential to reducing risks while maintaining advantages that are greater than possible disadvantages.

Economic and social impact

These new methods can potentially disturb established economic operations and production sectors. The widespread adoption of cleaner hydrogen and ammonia production will disrupt existing industrial methods until the established sectors stabilise in terms of employment and economic stability. The implementation demands a social impact assessment, economic analysis, and strategies to support communities that experience disruptions.

The successful implementation of biochar production demands proper regulation of its market demands and sustainable farming practices to avoid negative side effects.

UIC engineers have achieved history through hydrogen and nitrogen fusion, which presents future possibilities for modernising ammonia and hydrogen production methods. These new methods can achieve environmental and economic benefits, but researchers must develop effective ways to mitigate their catastrophic impacts.