Researchers have found a way to make stable and yet efficient solar panels made out of amorphous silicon solar cells and microcrystalline silicon tandem cells.

Amorphous silicon solar cells and microcrystalline silicon tandem cells have been found to be viable options for low-cost, high-yield industrial production of solar panels from abundant raw materials.

But to make solar made from these materials stable, they’re required to be very thin. This then presents the drawback of less conversion efficiency – or less than what crystalline wafer-based silicon currently can provide.

A joint effort between Oerlikon Solar and a group of researchers from the Institute of Physics’ photovoltaic group at the Academy of Sciences of the Czech Republic attempted to solve this problem.

The team’s new design focuses on optically thick cells that are strongly absorbing, even as the distance between the electrodes remains very tight.

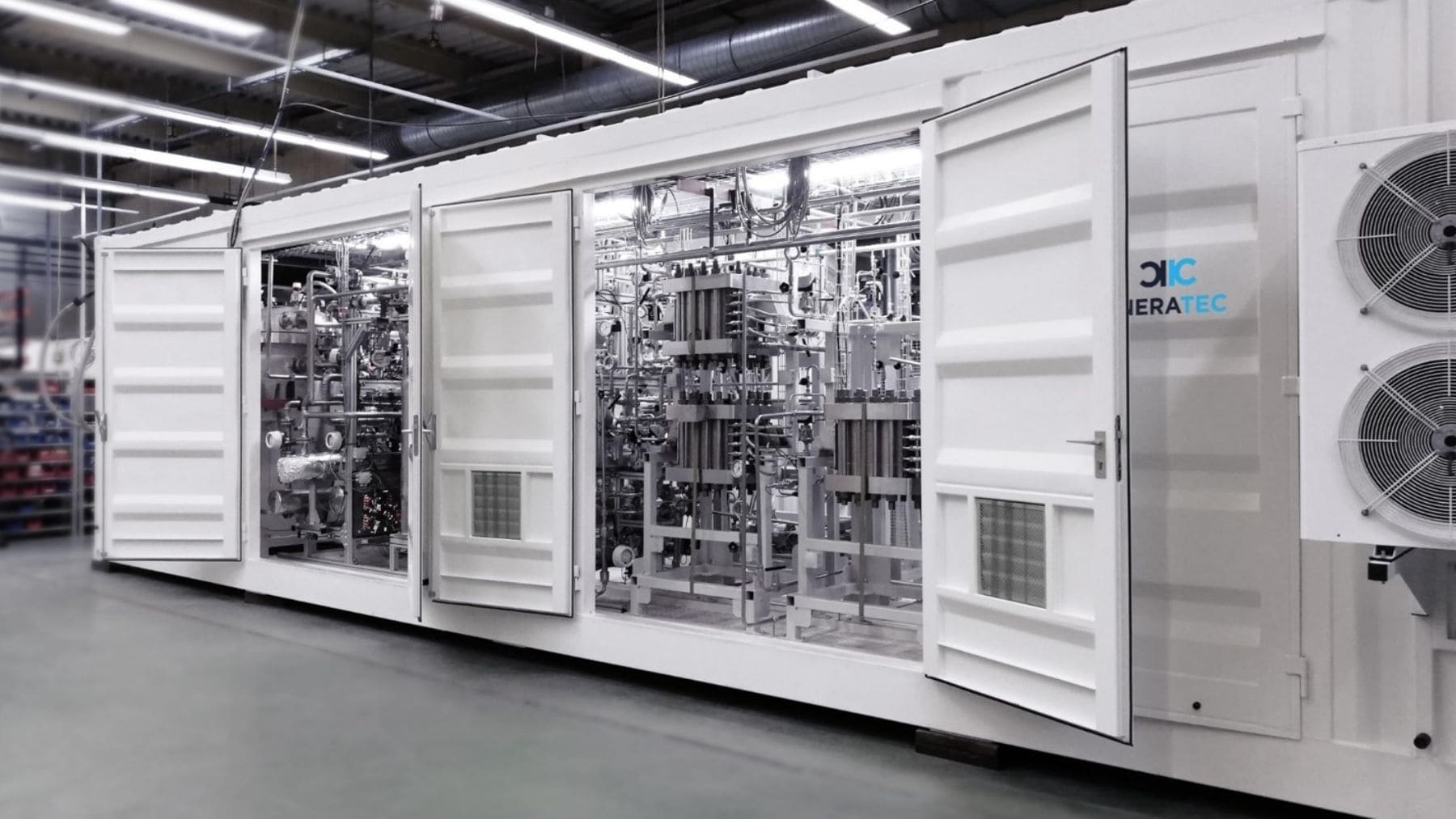

«Our new 3D design of solar cells relies on the mature, robust absorber deposition technology of plasma-enhanced chemical vapor deposition, which is a technology already used for amorphous silicon-based electronics produced for liquid crystal displays,” said Milan Vanecek, who heads the PV group.

“We just added a new nanostructured substrate for the deposition of the solar cell,» Mr. Vanecek says.

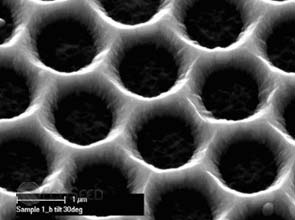

This nanostructured substrate consists of an array of zinc oxide nanocolumns or, alternatively, from a «Swiss cheese» honeycomb array of micro-holes or nano-holes etched into the transparent conductive oxide layer.

«This latter approach proved successful for solar cell deposition,» Mr. Vanecek elaborates. «The potential of these efficiencies is estimated within the range of present multicrystalline wafer solar cells, which dominate solar cell industrial production.

He said the significantly lower cost of Micromorph panels, with the same panel efficiency as multicrystalline silicon panels at 12 percent to 16 percent, could boost its industrial-scale production.

Overall, the new design for thin-film solar cells requires significantly less silicon – and may boost their efficiency.

The next step in the research is a further optimization to continue improving efficiency.

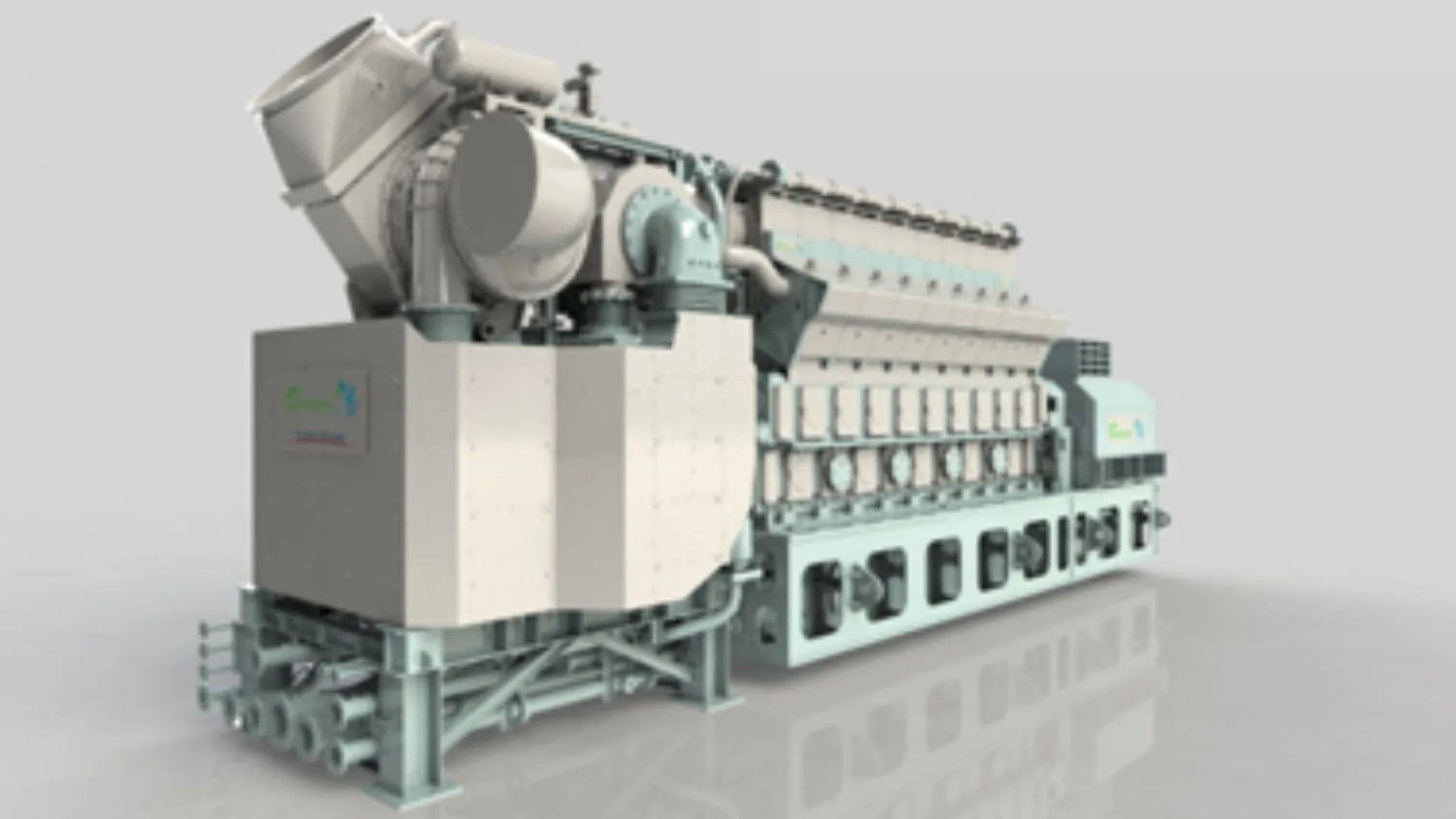

Oerlikon Solar is the solar segment of Swiss industrial company OC Oerlikon Corporation A.G.

Amorphous silicon panels have long been studied to be more efficient because it costs less to produce than crystalline silicon.

In July 2010, Gijs van Elzakker, a researcher from Delft University of Technology improved the efficiency of amorphous silicon panels by creating a silicon layer made of silane gas. The result was a solar cell with an efficiency of 9 percent.