The electric motor’s importance reverberates throughout the industrial sector – from HVAC systems, to fans and pumps, to the hard drives and servers of computer systems.

Electric motors, those devices that convert electrical energy to mechanical energy, are our basic tools for many essential activities in our daily lives. Your alarm clock, which woke you up, uses an electric motor. The elevator that brings you up and down your building has it.

The electric motor’s importance reverberates throughout the industrial sector – from HVAC systems, to fans and pumps, to the hard drives and servers of computer systems.

Globally, electric motors use a lot of power. According to a report from the International Energy Agency released in 2011, electric motors and the systems they drive are the single largest power suckers, taking in more than twice as much as lighting.

Electric motor driven systems account for between 43 percent to 46 percent of all global electricity consumption, leading to about 6,040 megatons of carbon dioxide emissions.

In terms costs, currently energy expended by the electric motor sector equates to about $565 billion per year. By 2030 that could become almost $900 billion.

Unless energy efficiency policy measures are put into place by 2030, energy consumption from electric motors will reach 13,360 terawatts per year, leading to 8,570 megatons of carbon dioxide emissions a year.

The first step toward lessening power use is the adoption of minimum energy performance requirements, or M.E.P.’s, for electric motors. Many countries are already in the process of developing such requirements and it is estimated that if all companies adopted best practice M.E.P.’s by 2030, around 322 terawatt-hours of annual electricity demand would be saved, along with about 206 million tons of carbon dioxide emissions.

According to the report, the potential exists to cost-effectively improve the energy efficiency of motor systems by around 20 percent to 30 percent. If we could manage to do that, it would result in a reduction of total global electricity demand by about 10 percent. Given the prevalence of the electric motor in so many vital sectors, improving its energy efficiency could become crucial for any economy with a more low-carbon future.

The same International Energy Agency found that the United States and Canada have taken the lead in setting motor efficiency standards, having introduced regulations for motors in the late 1990’s. The European Union also passed M.E.P. legislation for electric motors in 2009, while China defined M.E.P.’s for electric motors in 2002.

Australia, Korea, Brazil, Mexico, Taiwan, Costa Rica, Israel and New Zealand have also reportedly adopted M.E.P.’s. But some larger motor-using economies such as India, Japan and Russia have yet to adopt M.E.P.’s.

Electric vehicles

In the automobile market, according to Murali Krishna of EVhub, though small electric motors have been widely used for some time now, driving such operations like wiping windshields, the emphasis in the coming years would be bigger more powerful motors that could be capable of driving the entire vehicle.

With emphasis being put on slashing the emissions of the transportation sector, and major automakers rushing to outdo each other in releasing better hybrids with longer electric driving ranges, there is room for improvement in the electric motor’s performance.

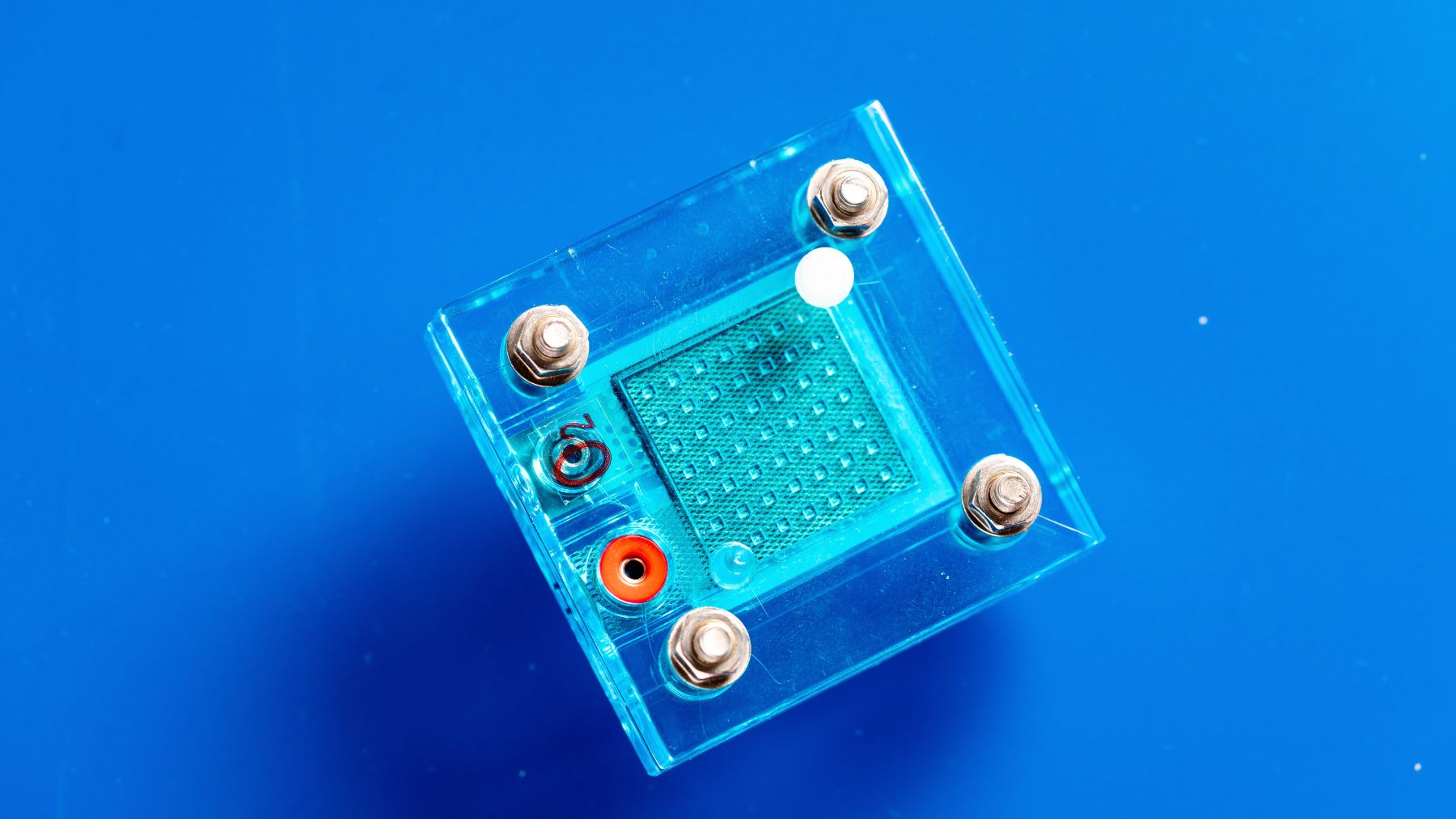

According to Mr. Murali, current electric motor technologies are usually alternating current induction motors, but the future would also see more brushless DC motors or BLDC motor.

“The cost of brushless DC is still higher because we use permanent magnets in the motors, but still it is important due to the higher efficiency and good controllability of the BLDC motor,” he said.

Because of their efficiency, while the initial cost of a BLDC motor might be higher than others in the market, in the long run they would actually be more cost effective, feels Mr. Murali.

“Energy efficiency is very important in an electric car,” Mr. Murali said.

Many applications for electric motors have already been found to be easily converted to BLDC motors such as water pumps, air conditioners and refrigeration units. (Katrice R. Jalbuena)

http://ecoseed.org/ – ECOticias.com